* The Su-7 started life as a tactical fighter, but ended up being an attack aircraft. Although its performance was good, it left something to be desired in other respects; however, it still ended up being heavily produced, and served with a number of air forces.

* Pavel Osipovich Sukhoi began his career as an aircraft designer in the 1930s, working for the experimental design bureau (OKB in its Russian acronym) run by Andrei N. Tupolev. By the time of the German invasion of the USSR in the summer of 1941, Sukhoi had graduated to leadership of his own OKB. However, although the Sukhoi OKB developed a number of promising designs, for various reasons none were all that successful, and as a result the OKB was shut down in 1949.

In 1953, shortly after the death of Soviet dictator Josef Stalin, Sukhoi was able to successfully lobby for another shot at running an OKB. The first task on the agenda for the revived Sukhoi OKB was development of a new tactical fighter and a new interceptor for the VVS (Voyenno Vozdushniye Sily / Red Air Force) -- both aircraft based on the advanced AL-7F afterburning turbojet, then in development at the engine OKB run by Arkhip Lyulka. Following recommendations from the state Central Aerodynamics & Hydrodynamics Institute (TsAGI in its Russian acronym), Sukhoi OKB came up with two fighter designs that were very similar, except for featuring different wing configurations:

Both machines had a "stovepipe" configuration, with the inlet in the nose and the exhaust in the rear; swept tail surfaces; a bubble canopy; and tricycle landing gear.

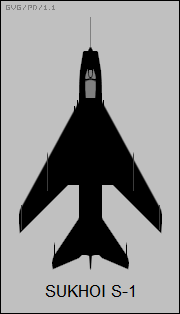

The delta wing proved a fairly good choice for high-altitude performance. The T-1 tactical fighter concept was abandoned, but the T-3 interceptor concept would evolve into the Sukhoi "Su-9", discussed elsewhere. The swept wing S-1 concept provided better low-altitude handling, making that design suitable for the tactical fighter role. Development was authorized, with a flight prototype and a static-test machine being built in 1955. The flight prototype of the S-1 first took to the air on 8 September 1955, with test pilot A.G. Kochyetkov at the controls.

The S-1 was a big step forward for Soviet aviation, and so test flights did not go all that smoothly, with the AL-7F engine proving very troublesome. However, the machine clearly had potential, with test pilot V.N. Makhalin attaining a level speed of 2,170 KPH (1,350 MPH) in April 1956 -- well faster than required by specification. Even before the type went to state trials, authorization had been given to build a batch of evaluation machines under the designation of "Su-7", recycling the designation of an unproduced Sukhoi piston-powered aircraft. The S-1 was put through its paces on 24 June 1956 at the Moscow-Tushino flyover; NATO observers took note of the type and assigned it the reporting name "Fitter" -- to be later retroactively designated "Fitter-A", when later "Fitter" variants appeared.

The S-1 configuration itself was not regarded as satisfactory for production, and so an "S-2" machine was built, first flying early September 1956, with test pilot Nikolay I. Korovushkin at the controls. The S-2 featured a number of changes from the S-1, including a stretched fuselage for more fuel capacity, and reduction of the S-1's armament of three Nudelman-Richter NR-30 30-millimeter automatic cannon in the wingroots to two NR-30s, one in each wingroot.

The original S-1 was lost in a crash on 23 November 1957. The aircraft suffered an engine failure, with the pilot, I.N. Sokolov, trying to "dead-stick" the machine back down to the runway; he didn't make it and was killed. The S-2 soldiered on in trials by itself until the first "production" Su-7 was built in the spring of 1958, being delivered from State Factory #126 at Komsomol'sk-na-Amure, in the extreme Soviet Far East on the Amur River. Incidentally, the term "Komsomol" was the name of the Soviet youth organization, which had helped build the town in the 1930s.

The initial-production Su-7 was built in small numbers -- it seems about 20 machines -- and used primarily for test and trials. While the aircraft had clear merit, it also suffered from a number of teething problems that had to be worked out before it could be introduced into operational service. A number of changes were incorporated through Su-7 production, such as a slightly lengthened nose; four pop-open auxiliary engine inlets around the intake; and a slightly uprated Al-7F-1 engine that required a modest expansion of the rear fuselage. The rear fuselage was also modified to provide "area ruling", a scheme in which the transonic handling of an aircraft was improved by ensuring gradual changes in cross-section, resulting in a "wasp-waisted" fuselage. A number of these modifications were evaluated on an initial-production Su-7 that was given the OKB designation of "S-41".

* Although the Su-7 itself was an air combat fighter, in 1956 the VVS had redirected the program to produce a fighter-bomber instead. In response, the Sukhoi OKB modified the S-2 design to the "S-22" configuration. The changes were not particularly noticeable, consisting mainly of airframe reinforcement, more internal fuel capacity via wing tanks, and stronger landing gear to handle the greater maximum take-off weight.

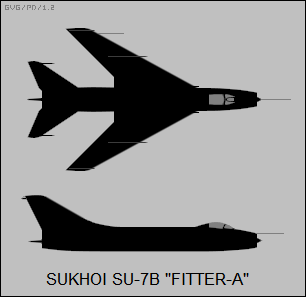

Initial flight of the first of two S-22 prototypes was on 24 April 1959, with test pilot Yevgeniy S. Solovyov at the controls. The type had already been ordered into production as the "Su-7B" -- the "B" standing for "bombardirovschik (bomber)" -- in July 1958. The Su-7B went into series production from the Komsomol'sk-na-Amure plant in 1960, to be formally accepted into VVS service in early 1961, with 431 built to 1963. The production machine retained the NATO reporting name of "Fitter-A". All the fixed-wing single-seat Su-7 variants would retain this reporting name.

BACK_TO_TOP* Although the Su-7 family would evolve considerably during its lifetime, the early Su-7B provides a useful baseline for description of the family. As it emerged, the Su-7B was a "flying stovepipe" with a fuselage featuring a circular cross-section, an inlet in the nose, mid-mounted strongly swept wings, and a strongly swept tail assembly. The aircraft was built very rugged, mostly of aviation aluminum -- the engine inlet featuring a moveable intake cone and feeding an AL-7F-1-100 turbojet providing 66.7 kN (6,800 kgp / 14,990 lbf) dry thrust and 90.2 kN (9,200 kgp / 20,280 lbf) afterburning thrust.

A small auxiliary gas turbine engine provided starting -- the auxiliary turbine used gasoline, not aviation fuel, and had its own fuel supply -- and a built-in engine fire-extinguisher system was fitted. Since the engine tended to flame out when unguided rockets were fired, causing intake gas ingestion, a system was added that throttled down the engine temporarily when the firing button was pressed. The engine intake cone could only be set to two positions originally, but was quickly updated to continuously variable positioning; the cone was set in the aft position in subsonic flight and was extended for supersonic flight. The cone accommodated an SRD-5M (NATO "High Fix") radar rangefinder, which complemented an optical computing gunsight. There was an air data boom above the intake; it was mounted on the centerline in early production, then shifted to the right in later production to get it out of the pilot's field of view. There was a second boom on the left wingtip.

There were dual auxiliary inlet doors arranged top & bottom on each side of the nose near the position of the windscreen, to provide additional airflow for take-offs. There were six ram inlets in the rear fuselage to provide cooling air to the engine afterburner. The rear fuselage could be pulled off from just behind the wings to give access to the engine.

The wings had a leading-edge sweep of 63 degrees, an anhedral droop of 3 degrees, an incidence of 1 degree, and a relatively high thickness / chord ratio of 5.7% at the wing root, thinning down to 4.7% at the tip. The wing featured hydraulically-actuated ailerons outboard and flaps inboard, as well as a large wing fence near the middle of the wing, and a small one near the wing tip. The fences prevented airflow from migrating (or "defecting" as some jokers put it) down the wing and off the wingtip. The tailplanes were all-moving, with each featuring a "barb" in the form of a balance weight near the tip, a feature found on a number of Soviet jets. The tailfin featured a hydraulically-actuated rudder. Four hydraulically-operated airbrakes were fitted in an "X" configuration around the rear fuselage. A brake parachute was stored in a compartment under the engine exhaust.

The Su-7B had tricycle landing gear, all with single wheels, all retracting hydraulically. The nose gear retracted forward, while the main gear hinged in the wings to retract inward towards the fuselage. The nosewheel could castor but was not steerable, with ground steering performed by selective application of main gear brakes. The nosegear leg length was increased in later production to reduce the aircraft's inclination to suck foreign objects into the engine intake. All the landing gear had hydraulically-actuated disk brakes. The gear was very strong and could support rough-field operations. There was a bumper under the tail to protect the aircraft from scraping the runway on take-offs and landings.

Internal armament included a single NR-30 cannon in each wingroot, with an ammunition load of 65 rounds per gun. There was a blast plate on the fuselage near the muzzle, and a gun camera in the right wing near the inboard wing fence. Internal fuel capacity was 3,455 liters (912 US gallons), in four bag tanks in the fuselage and one integral tank in each wing. This was not a big fuel supply for the thirsty AL-7F engine, and there were twin "wet" stores pylons arranged side-by-side under the fuselage that could each be fitted with a single external fuel tank with a capacity of 620 liters (164 US gallons).

There was a single stores pylon on each wing, just inboard of the main wing fence. All four stores pylons had a maximum load capacity of 500 kilograms (1,100 pounds). Some sources mention a built-in pop-open belly pack for unguided rockets, but this appears to be an error. A "toss-bombing" sight was fitted to permit delivery of tactical nuclear weapons, with the aircraft delivering the store in an upward "toss" to give the pilot time to get out of the blast radius.

The pilot rode in a pressurized cockpit under a canopy that slid back to open, sitting on a KS-2A ejection seat, which required a minimum altitude of 105 meters (350 feet) altitude for safe ejection. Early production had the less sophisticated KS-2 seat. The windscreen was fitted with armor glass and the cockpit was pressurized. Avionics systems were reasonably sophisticated, including radios, simple navigation aids, an SRO-2 Khrom (NATO "Odd Rods") identification friend or foe (IFF) transponder, a Sirena-2 tail warning radar, and a Kremniy-2 radar warning receiver (RWR). The Su-7B featured three (non-redundant) hydraulic systems, as well as a primary and an emergency pneumatic system.

BACK_TO_TOP* Even before the Su-7B entered first-line service, the VVS was asking for more range. The result was the "Su-7BM", the "M" standing for "modernizeerovanniy (modernized)", with the wing tankage altered to bring the internal fuel load to 3,755 liters (991 US gallons). The wing pylons were also made "wet" to permit carriage of four of the 620-liter drop tanks for ferry flights.

Other fixes included a system to reduce the threat of foreign object damage, using engine bleed air routed to a vent in the underlip of the engine intake to blow the path clear in front of the aircraft; an autopilot; improved avionics; an AL-7F-1-150 engine, with about 5% greater afterburning thrust, updated in later production to an AL-7F-1-200 engine with longer service life; and a KS-3 ejection seat. The Su-7BM entered VVS service in 1963, with 290 built to 1965.

___________________________________________________________________

SUKHOI SU-7BM "FITTER-A":

___________________________________________________________________

wingspan:

9.31 meters (30 feet 6 inches)

wing area:

34 sq_meters (366 sq_feet)

length:

16.6 meters (54 feet 6 inches)

height:

4.99 meters (16 feet 4 inches)

empty weight:

8,370 kilograms (18,450 pounds)

normal loaded weight:

11,730 kilograms (25,850 pounds)

MTO weight:

13,830 kilograms (30,840 pounds)

max speed at altitude:

2,120 KPH (1,315 MPH / 1,145 KT)

service ceiling:

18,500 meters (60,680 feet)

range with warload:

1,450 kilometers (900 MI / 780 NMI)

___________________________________________________________________

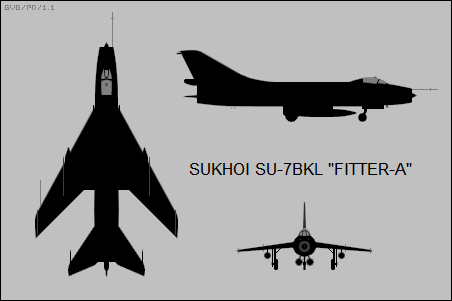

* The Su-7BM was followed in production by the "Su-7BKL", the primary change being modified landing gear for rough-field operation, with a larger hydraulically-steerable nosewheel, and main gear with auxiliary skids for operation on soft or snowy ground. The larger nosewheel required bulges in the nosewheel doors. The "KL" stood for "kolyosno lyzhnoye" or "wheel-ski landing gear". Incidentally, trials were also performed with pure ski main landing gear; it worked surprisingly well, but the wheel-ski landing gear was adopted instead.

Internal fuel load was raised again by modifying one of the fuselage tanks, to a total of 4,030 liters (1,063 US gallons). Larger external tanks, with a capacity of 950 liters (251 US gallons) were also supported, to later be replaced by 1,150-liter (303 US gallon) external tanks; in either case, only two of the large tanks could be carried, one on each wing pylon. Landing gear was reinforced to handle higher take-off weights. Other changes included:

By the late 1960s, Su-7s often carried an SPS-141 (or -142 or -143) radar jammer pod as an external store. The Su-7BKL went into service in 1965, with 267 built to 1971.

* An export version of the Su-7BKL, the "Su-7BMK", was introduced into production in 1965, parallel to manufacture of the Su-7BKL. It was very similar to the Su-7BKL except for being fitted with the older Su-7BM landing gear, a modified IFF system, and as a rule no toss-bombing computer -- the Soviets were not big on letting their allies have nuclear weapons, even on a controlled loan arrangement, though there were a few exceptions. A total of 441 Su-7BKLs was built to 1971.

BACK_TO_TOP* At the time the Su-7 series was going into widespread VVS service, the standard Soviet advanced trainer was the MiG-15UTI "Midget", which was seen as lacking the performance needed to properly familiarize pilots needed to fly the supersonic aircraft of the 1960s. After some informal studies from 1962, in 1964 the go-ahead was given for a tandem two-seat Su-7 series trainer, with the OKB designation of "U-22", where the "U" stood for "ubchebniy (trainer)".

Two prototypes were built, the first performing its initial flight on 25 October 1965, with test pilot Y.E. Kukushev at the controls. The type went into production as the "Su-7U" in 1966, with 367 built to end of production in 1971. Some were supplied to the Protivo Vozdushnoy Oborony (PVO), the Soviet national air defense service, distinct from the VVS. This was a bit puzzling since the PVO didn't use the Su-7, but the service was short on high-performance trainers and had to make do with the Su-7U. NATO assigned the type the reporting name "Moujik".

* The Su-7U was based on the Su-7BM airframe, with avionics, dual brakechute fairing, and RATO attachments from the Su-7BKL. A fuselage plug was added forward of the wing to stretch the length by 20 centimeters (8 inches) to permit fit of the second cockpit. There was a noticeable spine running from the cockpit to the tailfin that accommodated wiring and piping. The spine was added just to get these elements away from the hot engine.

There was a barrier between the front and rear cockpit, with the instructor in the back seat communicating with the student in front over an intercom. The two cockpit sections were separately pressurized, and each had its own rear-hinging clamshell canopy. The rear seat was not raised, and so the instructor had a poor view forward; to compensate, a periscope that popped up when the landing gear was extended was mounted over the top of the rear canopy. This was a common trick in Soviet operational conversion jet trainers. Both student and instructor sat on KS-4 ejection seats, using a system that ensured they fired in sequence instead of together, in order to reduce the possibility of collision.

The landing gear was modified with a liquid cooling system to permit a high rate of take-offs and landings, as would be required in training. The aircraft was in principle combat capable, retaining the twin NR-30 cannon and combat avionics, though the second seat meant a smaller internal fuel capacity and higher empty weight meant a smaller warload. Only a single stores pylon could be fitted under each wing. An AL-7F-1-200 engine was fitted.

An export version, the "Su-7UMK", was built in parallel with the Su-7U from 1968 up to end of production, with 44 produced in all. It was effectively identical, except for a different IFF unit and other minor equipment changes. It of course retained the "Moujik" reporting name.

* Su-7s were used for various test and trials purposes well into the 1980s, long after the type was obsolete. Among the more interesting of these modifications were three Su-7Us that were fitted out as ejection seat testbeds, with the rear cockpit modified for the test seats. Single-seat Fitter-A machines were used for various munitions trials. One was used in the late 1980s to help train cosmonauts to land the "Buran" space shuttle, which never actually performed a piloted spaceflight.

BACK_TO_TOP* The "Fitter-A" was an early Soviet supersonic fighter, and it suffered from limitations found in many of its contemporaries, in particular low endurance and range along with a light warload -- about 1,000 kilograms (2,200 pounds). Typical warloads included:

With the second stores pylon attached to each wing, two relatively small stores could be carried under each wing, with typical total warloads being:

Flying the "Fitter-A" without belly tanks was possible, allowing it to carry two more stores -- but it was almost out of the question, since the range would be uselessly short.

The Su-7 also suffered from a long take-off run and a hot landing speed -- it would stall out at a relatively high speed and slam into the ground short of the runway if a pilot wasn't careful. That was why the dual brake chutes were introduced, to allow a pilot to come in fast, and then kill his speed after touchdown -- a procedure that only pilots fond of extreme excitement particularly liked. The RATO gear was supposed to help with the long take-off run, but the RATO boosters were expensive and they were only infrequently used. The controls were also heavy, though that was compensated for by a reliable and effective autopilot.

On the plus side, the twin NR-30 cannon were very hard-hitting -- firing a 30 x 155 millimeter cartridge, as compared to the less potent Western Aden / DEFA 30 x 113 millimeter cartridge; the aircraft was a very stable gun platform; it handled well, capable of flying very smooth and fast at low level, and in fact was a dangerous customer for any adversary trying to take it on at low altitude. It was in particular extremely rugged, a real plus in a strike fighter. Su-7s that bellied in on a gear-up landing were usually just patched up immediately and put back on flight status, and the AL-7F engine could swallow with little more than a hiccup foreign objects that would all but wreck a comparable Western engine. It is said there wasn't a single NO STEP label anywhere on the aircraft, and it was possible to do pull-ups on the pitot boom.

* The Su-7 series became one of the mainstays of tactical strike for the VVS. It also proved popular in export, serving with Warsaw Pact air forces, as well as the air forces of Afghanistan, Algeria, Cuba, Egypt, India, Iraq, Libya, North Korea, Syria, and Vietnam. India was a particularly enthusiastic user, obtaining about 230 Su-7BMKs and Su-7UMKs. In VVS and Warsaw Pact service, at least early on "Fitter-As" were left in natural metal colors. That not being a practical measure for a low-level strike aircraft, eventually camouflage schemes became more or less standard -- light blue on the bottom, disruptive patterning on top, the patternings varying from place to place, examples being brown and green, sand and brown, or green with sand and brown.

Although the Su-7 series never saw any real combat with the VVS, it participated in a number of wars with foreign air arms using the type. The Egyptians had several dozen Su-7BMKs in service at the start of the June 1967 Mideast war, with a number destroyed on the ground and the rest doing little to distinguish themselves. However, the Soviets quickly built the Egyptian Air Force (EAF) back up to strength and the Su-7 proved a useful weapon in the regional squabbles over the next few years, able to strike at Israeli targets in the Sinai and exit the battle area too fast to permit interception by Israel fighters. It was also used for fast tactical reconnaissance, carrying a pod fitted with British Vinten film cameras. The Su-7 provided useful service during the November 1973 Mideast War. The Egyptians liked the type so much that many were refurbished in the 1980s, with the updates featuring improved avionics.

The Indian Air Force found the Fitter-A very useful during the 1971 Indo-Pakistan War, with the type flying a total of about 1,500 sorties, with not one shot down, even though they had to fly in the face of intensive ground fire. Two were hit by Pakistani Sidewinder air-to-air missiles (AAM) and both made it back home.

* Overall, pilots seemed to generally like the machine, though they were aware of its limitations, and there were those who were rightfully frightened of its excessive landing speed. Some sources do suggest that VVS brass found it a disappointment, not much more effective than the old Mikoyan MiG-17s pressed into service as strike fighters. However, the Soviets had a custom of methodical persistence, and the virtues of the Su-7 seemed substantial enough to make it worthwhile to see what might be done to deal with its faults. This effort would lead to an entirely new generation of "Fitters" that would replace the "Fitter-A" -- which would generally fade out of service in the 1980s.

* 1,862 Su-7s were built in all. The following list summarizes Su-7 variants and production: