* In the period following World War I, the de Havilland company of Britain (DHUK) decided to tap into popular interest in flying by developing a good, low-cost light aircraft, the "Moth", for the civil market. It proved successful and led to a series of follow-on Moth designs, most notably the "Tiger Moth", that proved their worth in civil and military trainer roles. This document gives a history and description of the de Havilland Moth family. Illustration credits are included at the end.

* The British Airco aircraft manufacturing firm was founded in 1912, acquiring Geoffrey de Havilland as chief designer in 1914. He would design a series of military aircraft for the firm, such as the "DH.4" single-engine light bomber, that saw extensive service in World War I. De Havilland set up his own firm in 1920, initially just producing aircraft he had designed for Airco, adding minor improvements.

With the war over, de Havilland became interested in aircraft for civil use, developing a series of small airliners -- to be discussed elsewhere -- and aircraft for private use. In 1922, the de Havilland firm ("DHUK" for short) flew the three-seat "DH.37" touring aircraft, following it up in 1924 with the refined three-seat "DH.51" touring aircraft. They were not successful, with only two DH.37s and three DH.51s built.

In the meantime, in response to a contest set up by the DAILY MAIL newspaper for what would now be called an "ultralight" aircraft, the goal being to make sport flying available to more than rich playboys, de Havilland built two prototype "DH.53 Hummingbird" low-wing monoplanes, with initial flight in 1923. They were very little aircraft, with an empty weight of only 148 kilograms (326 pounds), their first powerplant being a Douglas motorcycle engine. The motorcycle engine was quickly replaced by a Blackburne Tomtit air-cooled two-cylinder vee engine with all of 19 kW (26 HP) power -- a "Tomtit", by the way, is a little New Zealander songbird.

Although the British Royal Air Force (RAF) bought eight production Hummingbirds and private buyers obtained five, de Havilland didn't think it was the aircraft that he really wanted to build; it was simply too toylike, at least two seats were needed, and as with any ultralight, it was too daring for a casual and inexperienced pilot. That led him to think of a larger and more capable, if still lightweight, aircraft; using the DH.51 as a model, de Havilland developed a smaller two-seat derivative, the "DH.60", which performed its initial flight on 22 February 1925, de Havilland himself being at the controls. The British Air Ministry found the DH.60 intriguing, and provided a subsidy to five UK flying clubs -- London, Lancashire, Midlands, Newcastle, and Yorkshire -- to equip them with the type.

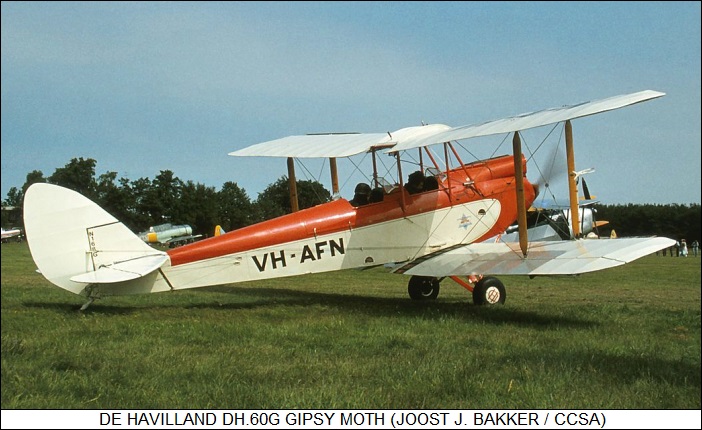

* The DH.60 was a generally conventional aircraft for the period, of biplane configuration, tractor engine mount, tailwheel fixed landing gear, and dual open cockpits; it had an empty weight about three times greater than that of the Hummingbird. The DH.60 was of wood and cloth construction, with spruce framing, plywood skinning on the fuselage, and cloth skinning on the flight surfaces. The wings were straight, while the tailfin and tailplanes were of "guitar pick" configuration. One interesting little feature was a streamlined fuel tank mounted in the top wing center section.

The DH.60 was originally powered by an air-cooled four-cylinder vertical inline ADC Cirrus I engine, providing 67 kW (80 HP). The engine had been designed by one Major Frank Halford for ADC, and was based on the French Renault vee-8 engine. In fact, the Cirrus I was essentially a Renault engine chopped in half, and used surplus Renault components in its construction. The DH.60's wings could hinge back along the fuselage for stowage. The hinged wings gave something of an impression of a moth, and since Geoffrey de Havilland was an enthusiastic butterfly collector, a "Moth" the DH.60 became. It seemed hopeful for penetrating the civil aviation market because of its low cost, sturdiness, reliability, and docile handling.

In 1926, the Cirrus I engine was replaced by the uprated Cirrus II engine, with 63 kW (85 HP), resulting in what would be called, of course, the "Cirrus II Moth". Some airframe modifications were introduced in 1927 including an increase in span, followed in 1928 by the introduction of the Cirrus III engine with 67 kW (90 HP), and more airframe modifications -- most notably a split axle for the main gear, replacing the old one-piece axle. The Cirrus III Moth was known as the "DH.60X", it seems because the split-axle scheme meant an "X"-shaped arrangement of landing gear bracing.

Apparently the "DH-60X" had been applied to the Cirrus II Moth for a while, the "X" in that case meaning "experimental". The history of the Cirrus Moths is a bit confusing, as are production totals; numbers of that series have been cited as at least 400 machines, including aircraft built by the General Aircraft Company (GAC) in Australia, as well as the Government Aircraft Factory and Veljekset Karhumaeki, both in Finland. A trustworthy breakdown of quantities would be very hard to obtain.

One of the series was experimentally fitted with an Armstrong Siddeley Genet five-cylinder air-cooled radial engine providing 60 kW (75 HP), this machine naturally being known as the "Genet Moth". Some sources claim that five more were built, going into service at the UK Government Central Flying School.

* The DH.60X was the end of the Cirrus-powered Moth line. As noted, Cirrus engines were dependent on Renault parts, and the parts were running out, meaning the Cirrus had no future. In addition, the Moth had been suffering from the curse of aircraft refinement, weight creep, and so a more powerful engine was required.

In 1926, de Havilland had Major Halford design a new engine derived from the Cirrus for the firm to produce itself, the result being the "Gipsy I" four-cylinder air-cooled inline engine, with 75 kW (100 HP). The new powerplant went into production in 1927; fitted with it, the Moth became the "DH.60G" -- though this designation was quickly extended by the more intuitive "Gipsy Moth". With DHUK producing both the aircraft and the engine, the aircraft could be sold at low cost. The Gipsy I was not only more powerful but also very robust, and the Gipsy Moth set a number of performance and distance records.

___________________________________________________________________

DE HAVILLAND DH.60G GIPSY MOTH:

___________________________________________________________________

wingspan:

9.14 meters (30 feet)

wing area:

22.57 sq_meters (243 sq_feet)

length:

7.29 meters (23 feet 11 inches)

height:

2.68 meters (8 feet 9 inches)

empty weight:

417 kilograms (920 pounds)

MTO weight:

748 kilograms (1,650 pounds)

max speed at sea level:

160 KPH (100 MPH / 85 KT)

service ceiling:

4,420 meters (14,500 feet)

range:

515 kilometers (320 MI / 280 NMI)

___________________________________________________________________

The Gipsy Moth was a great success, being reliable, easy to fly, and cheap. A luxury version, the "DH.60L", was built, featuring a larger luggage compartment, spiffy two-tone paint job, and other fripperies. A total of 595 Gipsy Moths was built by DHUK up to end of production in 1934; 40 were also built in France by Morane-Saulnier, these machines of course being named "Morane Moths", while 18 were built by the Moth Aircraft Corporation (MAC) in the USA, and 32 were built by the Larkin Aircraft Supply Company LTD in Australia.

* De Havilland recognized that the Gipsy Moth wasn't rugged enough for rough environments, and so a version with a metal welded steel tube fuselage was designed, this variant of course being named the "Metal Moth", or more officially "DH.60M". 536 were built in the UK, with 40 assembled by the de Havilland factory in Canada (DHC), plus 10 built in Norway and 161 built by MAC of the USA. The DH.60M was popular with military services, a fair number of them being obtained by the RAF and the Royal Canadian Air Force (RCAF), with numbers also obtained by the air forces of Iraq and Sweden; the Norwegian army; and the Danish naval air service.

The Gipsy engine, as with its ancestor the Cirrus, went through refinements, the first step being the Gipsy II of with 90 kW (120 HP); it was quickly modified as the Gipsy III to permit inverted operation, the main change being to simply flip the carburetor over, permitting a more streamlined engine installation and an improved field of view for the pilot. A Gipsy Moth was fitted with the Gipsy III, with this variant performing its first flight in March 1932 as the "DH.60III", with 30 built. The Gipsy III quickly led to the Gipsy Major IIIA engine, further uprated to 100 kW (133 HP); the result was the "Moth Major". Total production of these variants is given as 154.

In the meantime, DHUK had modified the Metal Moth to a military trainer specification as the "DH.60T Moth Trainer", featuring a Gipsy II engine and a reinforced airframe; it could also be fitted with a bomb rack for four practice bombs, a camera gun, or a reconnaissance camera. The cockpit doors were deepened, and the wing wiring slightly rearranged to aid in crew escape. 59 were built, being sold to a half dozen countries. However, the DH.60T was not seen as entirely satisfactory to its assigned role, and work was performed to improve it. As a result, the DH.60T was an interim type, and the last of the first-series Moths.

BACK_TO_TOP* The name "Moth" had acquired such a value in aviation circles as to ensure that de Havilland would use it for later designs, some of which had little or no relation to the DH.60. The next de Havilland aircraft to incorporate "Moth" into the name was the "DH.61 Giant Moth", which was really a small airliner, and so needs to be discussed along with the other prewar de Havilland airliners. The next was the "DH.71 Tiger Moth", which was a low-wing monoplane air racer, basically an experimental demonstrator, with only two built.

The first Moth that could honestly be seen as a descendant of the DH.60 was the "DH.75 Hawk Moth", which was a high-wing monoplane with wing bracing, featuring a steel tube airframe covered with cloth, fixed tailwheel landing gear, and with an enclosed cabin seating four. The first prototype performed its initial flight on 7 December 1928, this machine being powered by a de Havilland Ghost air-cooled vee-8 engine driving a two-bladed fixed-pitch propeller -- the Ghost being developed by Major Halford, amounting to two Gipsys jammed together in a vee arrangement, in an odd roundabout to the Gipsy's Renault vee-8 ancestor. Incidentally, Halford would continue to work on engines for DH into the jet age, and recycle the name of Ghost for a pioneering DH turbojet.

The Ghost inline could only provide 150 kW (200 HP), leaving the aircraft underpowered, so it was replaced by an Armstrong Siddeley Lynx IV seven-cylinder air-cooled radial engine with 180 kW (240 HP), the aircraft going into production as the "DH.75A", with wider wingspan and other changes. Only eight Hawk Moths were built in all, the type being experimentally fitted in Canada with floats -- an experiment that did not go very well -- as well as skis -- which went better. The last of the Hawk Moths was re-engined in 1935 with a Wright Whirlwind J-5 radial engine, providing 225 kW (300 HP), to be later re-engined in turn in 1943 with an Armstrong Siddeley Cheetah IX radial, essentially an improved Lynx, with 260 kW (350 HP).

___________________________________________________________________

DE HAVILLAND DH.75A HAWK MOTH:

___________________________________________________________________

wingspan:

14.33 meters (47 feet)

wing area:

31.03 sq_meters (334 sq_feet)

length:

8.79 meters (28 feet 10 inches)

height:

2.84 meters (9 feet 4 inches)

empty weight:

1,080 kilograms (2,380 pounds)

MTO weight:

1,655 kilograms (3,650 pounds)

max speed at altitude:

205 KPH (130 MPH / 110 KT)

service ceiling:

4,420 meters (14,500 feet)

range:

900 kilometers (560 MI / 485 NMI)

___________________________________________________________________

* The fit of the Cheetah was obviously experimental, since DHUK had long moved on to a better successor to the somewhat crude Hawk Moth, the "DH.80 Puss Moth". The Puss Moth had the same general configuration as the Hawk Moth -- monoplane, high wing with bracing, fixed tailwheel landing gear, enclosed cockpit, though seating was reduced to three -- but the Puss Moth was considerably smaller and also tidier, for example with spatted main landing gear. Most notably, it featured the Gipsy engine; an interesting feature was faired main-gear shock absorbers that could be pivoted for use as airbrakes.

The initial prototype performed its first flight on 9 September 1929 -- this aircraft apparently using a Gipsy II engine in an inverted installation, it being unclear just how well such an improvisation worked, and featuring a plywood-covered fuselage. Production machines, rolled out from March 1930, had a steel-tube, fabric-covered airframe with some configurational changes. Later production featured the Gipsy Major engine with 97 kW (130 HP), giving the DH.80 peppy performance for its class. Unfortunately, a wing flutter problem led to a number of fatal crashes, the issue being fixed with additional bracing.

___________________________________________________________________

DE HAVILLAND DH.80 PUSS MOTH:

___________________________________________________________________

wingspan:

11.20 meters (36 feet 9 inches)

wing area:

20.62 sq_meters (222 sq_feet)

length:

7.62 meters (25 feet)

height:

2.13 meters (7 feet)

empty weight:

574 kilograms (1,265 pounds)

MTO weight:

930 kilograms (2,050 pounds)

max speed at altitude:

205 KPH (130 MPH / 110 KT)

service ceiling:

5,340 meters (17,500 feet)

range:

480 kilometers (300 MI / 260 NMI)

___________________________________________________________________

259 production Puss Moths were built by DHUK in three years of production, with 25 more built by DHC. They set a number of long-distance flight records. Production was ended to make way for the Leopard Moth, discussed below.

* The next aircraft in the Moth numeric sequence was the "DH.81 Swallow Moth", which performed its first flight on 21 August 1931. It was a low-wing monoplane, with fixed tailskid landing gear but no wing braces, along with tandem seating for two -- originally with open cockpits, then with an enclosed cockpit -- and a Gipsy IV engine with 60 kW (80 HP). Only one Swallow Moth was built, the Great Depression meaning there wasn't a market for it at the time, and the aircraft effectively ending up being a demonstrator for later Moth design features.

BACK_TO_TOP* The DH.60T Moth Trainer was a reasonably successful aircraft, but it left something to be desired. The main problem was that, though changes had been made to aid crew escape, the wing struts still presented an obstacle; as a result, the struts were angled forward, resulting in the upper wing moved forward as well. That affected center of gravity, and so the wings were given a modest sweepback. They also acquired extensible slats on the outboard top wing, though it is unclear exactly when they were introduced into the Moth line; photos of the Gipsy Moth do not show the slats, and they may have been added to compensate for the wing sweepback.

The new version, the "DH.60T Tiger Moth", was fitted with a Gipsy III inverted inline engine, with eight pre-production machines built. The pre-production batch indicated a need for further improvements, the lower wing being given more dihedral and sweepback, with this "DH.82 Tiger Moth" performing its initial flight on 26 October 1931, and deliveries to the RAF beginning before the end of the year, the service designating the type as "Tiger Moth Mark I". The same variant was obtained by Brazil, Denmark, Portugal, and Sweden, with three built under license in that country; the RAF also obtained two machines fitted with floats built by Short Brothers.

DHUK refined the design by fitting it with a Gipsy Major I engine, and changing the rear fuselage from cloth to plywood skinning; the "DH.82A Tiger Moth Mark II" also featured a hood that could be fitted over the rear cockpit for blind flight training. The DH.82A was produced in considerable quantity, becoming the mainstay of RAF and reserve flight schools. It was also built in Norway, Portugal, Sweden, and by DHC.

In addition, DHUK built several hundred "DH.82B Queen Bee" radio-controlled target drones based on the Tiger Moth, featuring a larger fuel tank and a windmill-type electric generator to power systems. The first Queen Bee performed its initial flight on 5 January 1935; an additional batch was built by Scottish Aviation.

DHC went on to build a large number of "DH.82C" winterized trainers, which featured the Gipsy Major IC engine with 110 kW (145 HP); sliding cockpit canopies; cockpit heating; a modified cowling; and a tailskid instead of tailwheel. Skis or floats could be fitted in place of wheeled landing gear. Some DH.82C machines were fitted with the Menasco Pirate D.4 air-cooled four-cylinder inverted inline engine with 120 kW (160 HP) due to shortages of the Gipsy Major. The US Army Air Forces ordered 200 DH.82Cs as the "PT-24", but they were all diverted to the Royal Canadian Air Force (RCAF).

___________________________________________________________________

DE HAVILLAND CANADA DH.82C TIGER MOTH:

___________________________________________________________________

wingspan:

8.94 meters (29 feet 4 inches)

wing area:

22.2 sq_meters (243 sq_feet)

length:

7.29 meters (23 feet 11 inches)

height:

2.69 meters (8 feet 10 inches)

empty weight:

506 kilograms (1,115 pounds)

MTO weight:

828 kilograms (1,825 pounds)

max speed at sea level:

170 KPH (105 MPH / 90 KT)

service ceiling:

4,450 meters (14,600 feet)

range:

445 kilometers (275 MI / 240 NMI)

___________________________________________________________________

* With the outbreak of World War II, the RAF couldn't get enough Tiger Moths, impressing civil machines and ordering large batches of new aircraft. DHUK continued production at the company's Hatfield plant, before it was switched over to de Havilland Mosquito production. Morris Motors LTD then took up the slack, building thousands more. The Tiger Moth was also built in quantity by de Havilland plants in New Zealand and Australia.

Tiger Moths followed the British Expeditionary Force to France in the fall of 1939, performing communications duties up to the evacuation of British forces via Dunkirk in June 1940. With an invasion of the British Isles appearing imminent, racks were designed for the Tiger Moth to allow it to carry eight 9-kilogram (20-pound) bombs, either under the fuselage or under the lower wing. A total of 1,500 racks was built, but the Tiger Moth never dropped bombs in anger. There were also trials of use of the Tiger Month to dispense poison agents, and with a bizarre gimmick to slash the parachutes of German paratroopers.

The Tiger Moth was also used in coastal patrol; although unarmed, it could keep an eye out for German submarines, and its presence could make submarine skippers nervous. In the Burma theater -- on the tail end of the global supply queue and where improvisation was standard practice -- a few Tiger Moths were modified as air ambulances, with a single casualty carried on a stretcher in the rear fuselage, with the stretcher put in or taken out through a lid.

The Tiger Moth's major contribution to the war was as a trainer, of course. It equipped more than 28 training squadrons in the UK; 25 in Canada, along with 4 wireless schools; 12 in Australia; 4 in Rhodesia, plus a flight instructor school; 7 in South Africa; and 2 in India. The Queen Bee target proved important in the conflict as well. Many civilian Moths of various types were impressed into service for training and communications duties.

Although the detail production history of the Tiger Moth is very hard to sort out, more than 8,000 were built to the end of the conflict, with many being released to the commercial market after the war. They were used as civil trainers, sport aircraft, and crop dusters, Tiger Moth dusters being particularly favored in New Zealand. There were also a number of conversions, most spectacularly the Thruxton Jackaroo, with an enclosed cabin seating four, 19 such conversions being performed in the late 1950s.

* The Thruxton Jackaroo wasn't an entirely new concept, DHUK itself having built a passenger derivative of the Tiger Moth before the war. In 1932 A.E. Hagg, the company's chief designer, worked to develop an economical light airliner based on the Tiger Moth, with the "DH.83 Fox Moth" prototype performing its initial flight on 29 January 1932. It was essentially a Tiger Moth with a new, wood-framed / plywood-skinned fuselage featuring the pilot in an open cockpit towards the rear, and a cabin seating three passengers straddling the wing center section.

The prototype was powered by the Gipsy III engine; most production machines were powered by the Gipsy Major, and some "Speed Models" had a sliding canopy over the cockpit.

___________________________________________________________________

DE HAVILLAND DH.83 FOX MOTH:

___________________________________________________________________

wingspan:

9.41 meters (30 feet 11 inches)

wing area:

24.25 sq_meters (261 sq_feet)

length:

7.89 meters (25 feet 9 inches)

height:

2.68 meters (8 feet 10 inches)

empty weight:

500 kilograms (1,100 pounds)

MTO weight:

940 kilograms (2,070 pounds)

max speed at altitude:

180 KPH (115 MPH / 100 KT)

service ceiling:

3,870 meters (12,700 feet)

range:

580 kilometers (360 MI / 315 NMI)

___________________________________________________________________

98 Fox Moths were built by DHUK between 1932 and 1935, with two more built by DH Australia. The Japanese Gasuden firm built an unlicensed clone, powered by a 112 kW (150 HP) radial engine, as the "Chidorigo (Plover) with about eight built. Another 53 "DH.83C" machines were built after the war by DHC -- no "DH.82A" or "DH.82B" variants were actually built. The DH.83C featured a sliding canopy for the pilot and Gipsy Major IC engine, with 110 kW (145 HP).

BACK_TO_TOP* The DH.83 Puss Moth having proven successful, DHUK decided to rethink the design, with the first "DH.85 Leopard Moth" performing its initial flight on 27 May 1933. It had the same general configuration as the Puss Moth -- high braced wing, spatted tailwheel landing gear, inverted inline engine, and three seats -- and was of similar size, but it was a substantially different design in detail, featuring a wood framed / plywood skinned fuselage instead of a steel tube fuselage, as well as tapered folding wings. It was fitted with a Gipsy Major engine. 133 Leopard Moths were built over three years of production.

___________________________________________________________________

DE HAVILLAND DH.85 LEOPARD MOTH:

___________________________________________________________________

wingspan:

11.43 meters (37 feet 6 inches)

wing area:

19.14 sq_meters (206 sq_feet)

length:

7.47 meters (24 feet 6 inches)

height:

2.67 meters (8 feet 9 inches)

empty weight:

635 kilograms (1,405 pounds)

MTO weight:

1,010 kilograms (2,225 pounds)

max speed at altitude:

220 KPH (135 MPH / 120 KT)

service ceiling:

6,550 meters (21,500 feet)

range:

1,150 kilometers (715 MI / 620 NMI)

___________________________________________________________________

* About a year after the initial flight of the Leopard Moth, on 9 May 1934, the first prototype of the "DH.87 Hornet Moth" took to the air. It looked much like the Leopard Moth, except for being a biplane and having no spats on the main gear; construction of the Hornet Moth was like that of the Leopard Moth, but the Leopard Moth was slightly smaller, and only had seating for two. It was powered by a Gipsy Major engine.

It appears the DH.87 was originally designed as a replacement for the Tiger Moth in the training role, the enclosed cockpit making the aircraft less a trial in poor weather, and side-by-side seating being better suited for ab initio training. However, there was no interest from the RAF, so it was sold to the civil market instead.

___________________________________________________________________

DE HAVILLAND DH.87 HORNET MOTH:

___________________________________________________________________

wingspan:

9.73 meters (31 feet 11 inches)

wing area:

20.44 sq_meters (220 sq_feet)

length:

7.61 meters (25 feet)

height:

2.01 meters (6 feet 7 inches)

empty weight:

565 kilograms (1,214 pounds)

MTO weight:

885 kilograms (1,950 pounds)

max speed at altitude:

200 KPH (125 MPH / 110 KT)

service ceiling:

4,510 meters (14,800 feet)

range:

1,000 kilometers (620 MI / 540 NMI)

___________________________________________________________________

Deliveries of the production "DH.87A", with a revised wing, began in 1935. A further refined wing with squared-off wingtips was introduced in the course of production, resulting in the "DH.87B". A total of 165 Hornet Moths was built, including prototypes.

* The last of the "official" Moth line was the "DH.94 Moth Minor". It was effectively a resurrection of the DH.81 Swallow Moth with modest refinements. The first Moth Minor flew on 22 June 1937. By the beginning of the Second World War, 71 had been built, including nine "Moth Minor Coupe" machines with a ramped-up rear fuselage and a hinged cabin top.

Once the war broke out, other priorities shut down production of the Moth Minor in Britain, but production specs and tooling were sent to de Havilland Australia, which built 40 more.

___________________________________________________________________

DE HAVILLAND DH.94 MOTH MINOR:

___________________________________________________________________

wingspan:

11.15 meters (36 feet 7 inches)

wing area:

15.05 sq_meters (162 sq_feet)

length:

7.44 meters (24 feet 5 inches)

height:

1.93 meters (6 feet 4 inches)

empty weight:

445 kilograms (985 pounds)

MTO weight:

705 kilograms (1,550 pounds)

max speed at altitude:

190 KPH (120 MPH / 105 KT)

service ceiling:

5,030 meters (16,500 feet)

range:

485 kilometers (300 MI / 260 NMI)

___________________________________________________________________

The Moth Minor was indeed a minor player in the Moth line, but it did pave the way for the DHC Chipmunk trainer, clearly an evolution of the Moth line, which was built in numbers in the postwar period. Almost 10,800 Moths of all types were produced in all.

BACK_TO_TOP* Quite a few Moths remain airborne, most of them Tiger Moths, but there are a few other survivors, including at least one Fox Moth. Replicas have been manufactured of the Tiger Moth -- no hint of "remakes" of other Moths -- with the Fisher Company of the USA selling an 80%-scale ultralight clone, the "R-80", with engine options including Wankel-type rotaries or air-cooled flat-fours. It would be fun to say they named it the "Mini-Moth", but alas they weren't so inclined.

Production quantities of the different Moth variants tend to differ from source to source, so the quantities cited in this document have to be regarded as ballpark estimates.

I'd never given much thought to writing a document on the de Havilland Moth series until the summer of 2013, when I was working in the yard and heard the drone of aircraft engines overhead. I looked up and noticed three little piston types overhead, one a biplane -- with swept-back wings. "A Tiger Moth! Cool!" I was immediately inspired to write this document; I don't have a bottomless supply of enthusiasm, and I have to take advantage of it when I get it.

* Sources include:

I also obtained some details from the online Wikipedia. The Moth family is not over-documented.

Illustration credits:

* Revision history:

v1.0.0 / 01 oct 13 v1.0.1 / 01 sep 15 / Review & polish. v1.0.2 / 01 aug 17 / Review & polish. v1.0.3 / 01 jul 19 / Review & polish. v1.0.4 / 01 may 21 / Review & polish. v1.0.5 / 01 apr 23 / Review & polish. v1.0.6 / 01 apr 25 / Review & polish.BACK_TO_TOP