* The Mosquito was an innovative machine, reflecting unconventional thinking in both operational concept and manufacture. It had to overcome stiff official resistance before it was finally accepted for service. Once it was, it was built in the thousands, with dozens of marks.

This chapter describes the origin and technical evolution of the Mosquito. The number of different variants makes description difficult and confusing, and the cleanest approach is to break down the variant descriptions by category. Details of operational service are described in the next chapter. To further simplify the discussion, a few postwar Mosquito conversions and foreign-built Mosquito variants are also discussed in the next chapter, since they amount to something of a footnote.

* Captain Geoffrey de Havilland made his first mark on aviation through the "DH.4" light bomber of World War I, but in the postwar period the company mostly focused on the emerging field of commercial flight. The DH company's "DH.3H" single-engine biplane air transport of the early 1920s was a landmark in the field, and by the early 1930s the company had moved on to the more sophisticated "DH.84 Dragon" and "DH.89 Dragon Rapide" twin-engine transports, as well as the similar four-engine "DH.86" biplane transport. DH also became well-regarded for trainers and light civil aircraft, including the "DH.60 Moth", the "DH.60G Gipsy Moth", and the "DH.82 Tiger Moth".

In 1934, DH made a splash when the "DH.88 Comet" won the Victorian Centenary Air Race from Mildenhall, England, to Melbourne, Australia. Only five DH.88s were built; they were all hand-made, optimized as long-range air racers, with little or no intent to go into production. The Comet incorporated the latest technological advances, being a sleek low-wing monoplane with retractable landing gear and two souped-up Gipsy Six inline air-cooled engines. The Comet set a number of speed and distance records.

A few weeks after the Comet's triumphant arrival in Melbourne, DH decided to use concepts explored with the air racer to build a new four-engine intercontinental mailplane, the "DH.91 Albatross", designed by A.E. Hagg. The first of two DH.91 prototypes performed its initial flight on 20 May 1937.

The Albatross must have looked incredibly futuristic at the time, and it certainly made the likes of the biplane Dragon Rapide seem quaint. The DH.91 was a sleek, elegant low-wing monoplane aircraft, with twin tailfins and retractable landing gear, and appears to have had a great influence on the design of the later Lockheed "Constellation" piston airliner, which performed its first flight in 1943.

The DH.91 was powered by four Gipsy Twelve air-cooled engines, with 390 kW (525 HP) each and driving constant-speed propellers. Its airframe was built mostly of wood, using techniques pioneered in the DH.88 Comet. The wooden construction of the Albatross seemed like a throwback at a time when aircraft manufacturers were moving towards all-metal aircraft, but in fact it looked as much or more forward to modern composite-construction aircraft as it did to the older wood-and-cloth machines.

The airliner's construction was based on glues, allowing elimination of fasteners, and as with a modern composite aircraft the advanced wood construction reduced aircraft weight and allowed smooth, elegant, aerodynamically efficient curves that would be difficult to implement with metal structures.

The Albatross's wings were made in one piece with spruce spars and sheathing. The fuselage was constructed of a wood sandwich with a balsa core and plywood sheathing. The engine installation was particularly clean, with elegant slender cowlings and circular ram-air inlets in the leading edge of the wing on each side of each engine to provide cooling air for the engine radiators.

___________________________________________________________________

DE HAVILLAND DH.91 ALBATROSS:

___________________________________________________________________

wingspan:

32 meters (105 feet)

wing area:

100.15 sq_meters (1,078 sq_feet)

length:

21.79 meters (71 feet 6 inches)

height:

6.78 meters (22 feet 3 inches)

empty weight:

9,630 kilograms (21,230 pounds)

max take-off weight:

13,380 kilograms (29,500 pounds)

max speed at altitude:

360 KPH (225 MPH / 195 KT)

service ceiling:

5,455 meters (17,900 feet)

range:

1,675 kilometers (1,040 MI / 905 NMI)

___________________________________________________________________

The flight test program ran into a number of difficulties. The first prototype had to perform a wheels-up landing on 31 March 1938 when the landing gear refused to go down, and the second prototype broke in half on landing a few months later while it was performing overload trials. Both prototypes were repaired and put back into flight operations.

Imperial Airways ordered five DH.91s in airliner configuration with accommodations for 22 passengers, more windows, and slotted flaps, with these aircraft delivered between October 1938 and June 1939. In 1940, the two prototypes were pressed into British Royal Air Force (RAF) service on the Iceland run, while the five airliners remained in passenger service.

It appears that DH hadn't quite got the recipe correct for an advanced wooden aircraft with the Albatross, since some records report that it flexed excessively in flight and that the wooden structure quickly rotted. In any case, no DH.91s survived the war, with those that weren't lost in accidents scrapped in 1943. With only seven built and an undistinguished service career, the Albatross was hardly a success on its own terms, even though it was an elegant design. It would become memorable for what would follow it.

In early 1936, the British Air Ministry issued a specification titled "P.13/36" for a new medium bomber. In response, in April 1938, DH began design work on a derivative of the Albatross, fitted with two of the new and very promising Rolls-Royce "Merlin" vee-twelve water-cooled engines. The proposal was rejected since it didn't meet performance specifications. Other factors in the rejection were that DH hadn't designed a combat aircraft since World War I, and the Air Ministry didn't like the wooden structure.

The P.13/36 specification would eventually result in the Avro "Lancaster" and Handley-Page "Halifax" heavy bombers. However, instead of being a dead end, the DH submission would lead to something new, different, and spectacular.

BACK_TO_TOP* In 1938, with war looming, Britain was under pressure to rearm as fast as possible. That meant DH was under pressure to get to work building combat aircraft, or the company might well end up in the second-string role of building subassemblies for the aircraft companies that did.

The P.13/36 proposal had specified nose and tail turrets. The fact that the DH submission had proven underpowered using just two Merlin engines might have provoked the company's engineers into building just another bomber with four Merlins, but in a brilliant stroke of Zen thinking the engineers came up with an idea: Why not stay with the twin engines, get rid of the defensive armament, and obtain protection through simple speed?

The idea fed on itself. With no defensive armament, the crew could be reduced, making the aircraft still lighter. A smaller aircraft with a smaller crew would be in principle cheaper and easier to build, support, and fly than a larger aircraft, and would put fewer aircrew at risk. The latest types of Merlin engines, the "Merlin XX" series with a two-speed single-stage supercharger, were offering increased horsepower that could provide outstanding performance.

A design team under chief engineer Ronald E. Bishop came up with a concept designated the "DH.98" that could carry two crew and a bombload of 450 kilograms (1,000 pounds) over a range of 2,400 kilometers (1,500 miles) at a maximum speed of almost 655 KPH (400 MPH). It would be even faster than a Spitfire fighter.

A fast unarmed bomber was very contrary to British Air Ministry thinking at the time. There were concerns that the Germans would simply field faster fighters; that two crew weren't enough; that a bomber needed to have some defensive armament. DH engineers knew that if they compromised the design to any great extent by adding crew or gun turrets, it would then become just another medium bomber of no particular merit, so the company insistently stayed with the configuration.

Despite the fact that the Air Ministry felt that wooden aircraft were obsolete, the wood construction actually turned out to be something of a plus. With the mad scramble to get weapons production ramped up for war, Britain was facing shortages of raw materials, and the DH.98's wooden construction would relieve the pressure on metal supplies. That might have not been enough to turn the Air Ministry around, but DH found an ally in Air Marshal Sir Wilfrid Freeman, a friend of Geoffrey de Havilland back to World War I and a member of the Air Council that provided the government with advice on matters aeronautical. Freeman was a common-sensible person who understood and appreciated the fast-bomber concept, and more importantly was willing and able to challenge organizational conventional wisdom.

When DH pitched the DH.98 concept to the Air Ministry again in September 1939, a few days after the outbreak of war with Germany, construction of prototypes was authorized. The aircraft was partly pushed through by emphasizing its potential as a photographic reconnaissance machine, since Britain lacked a long-range reconnaissance aircraft at the time.

* DH was formally told to go ahead with full development on 29 December 1939, while the Air Ministry drew up Specification "B.1/40" around the design, awarding a contract for construction of a single prototype on 1 January 1940. The company hadn't waited for the contract to proceed, having set up the design team for the new machine in their own facility in early October. The engineers worked out of a rented manor named Salisbury Hall, not far from the DH Hatfield plant. It was an ancient place with a moat, where King Charles II's famous mistress Nell Gwynne had lived in the 17th century. Residents claimed she haunted the place, the evidence being the occasional sound of the rhythmic squeaking of her four-poster bed late at night. Winston Churchill's American mother Jennie Jerome Churchill, another mistress of the great and powerful, also lived there before World War I.

Salisbury Hall was selected not for its historical interest, but for its relative seclusion and its spacious facilities. Geoffrey de Havilland felt that the engineers would work faster if they were left in peace, and it also provided secrecy. The mock-up was built in the enormous kitchen, suspended from the ceiling. A hangar disguised as a barn was built on the manor estate for construction of the prototype.

Good progress with prototype development led to a contract on 1 March 1940 that confirmed construction of the prototype and added an order for 49 more DH.98s, to be built as reconnaissance-bombers. The DH.98 was not out of the woods quite yet, however. After the fall of France and the evacuation of the British Army at Dunkirk that spring, Britain seemed to be facing imminent invasion. Lord Beaverbrook, the new Minister of Aircraft Production, not unreasonably focused on producing existing types instead of development of new machines, and there was no available production capacity for new aircraft at the time. In fact, DH was busy fitting Tiger Moth trainers with bomb racks in expectation of German landings.

Beaverbrook told Freeman several times to halt the project, which was known in some circles as "Freeman's Folly", but Freeman stalled for time and pushed the effort. Britons were being armed for home defense in the summer of 1940, and Freeman kept a tommy gun in his office; he was so determined to drive ahead with the DH.98 that there were those who thought he might shoot "the Beaver" if the Mosquito was canceled. Whether from persuasion or threats, Beaverbrook came around in July 1940 and decided that the project should continue, as long as it did not interfere with DH's priority war work.

* The threat of invasion faded in the fall of 1940 -- the Germans had never really had the amphibious capability to pull it off anyway -- and DH engineers working on the DH.98 breathed easier and went on with their efforts. There was a tragic interruption in the work on 3 October 1940, when a German Junkers Ju 88 bomber came in low before the Hatfield plant and bounced four bombs over the wet grass into the buildings. 21 people were killed, 70 injured, and considerable amount of material needed for DH.98 development was destroyed. The Ju 88 didn't make it back home, being shot down over Britain and the pilot captured. As it turned out, he was thoroughly familiar with the target, having attended the de Havilland Technical School at the site before the war.

Despite the delay, prototype development moved ahead quickly. The prototype was dismantled and trucked from the "barn" at Salisbury Hall to Hatfield on 3 November, where it was reassembled, if with some difficulty since the assemblies proved reluctant to mate up again. Its initial flight was on 25 November 1940, with Geoffrey de Havilland JR, the company's chief test pilot, at the controls. The prototype originally had the serial "E-0234", but this was quickly changed to "W4050".

The machine was painted bright yellow in hopes of discouraging anti-aircraft gunners from taking potshots at the unfamiliar aircraft. W4050 was fitted out as a bomber, but it demonstrated the speed and agility of a leading-edge fighter, justifying the faith of the aircraft's backers. Wilfrid Freeman was no longer in the Ministry of Air Production, having left to become Vice Chief of the Air Staff at the beginning of November, but it still had to be gratifying to know that his "Folly" was flying.

A fighter DH.98 was now considered a high priority. British shipping losses from Focke-Wulf Fw 200 Kondor long-range ocean patrol aircraft indicated a need for a long-range fighter to shoot down the raiders. As a result, in July 1940, the initial order for 50 DH.98s had been changed from the original request for one initial prototype and 49 reconnaissance machines -- to the prototype, 19 reconnaissance machines, and 29 fighters, with the fighter defined under Air Ministry specification "F.21/40".

With the switch of the Luftwaffe from daylight bombing raids on Britain to night attacks in the fall of 1940, the DH.98 was also seen as a potential night fighter. A specification for such a variant was issued in October with the designation "F.18/40", though apparently there was no commitment to production for the moment.

On 29 December, W4050 went through its paces for Beaverbrook, Freeman, and other dignitaries. The next day, the Air Ministry issued an order for 150 more day fighter versions of the DH.98s. By this time, the aircraft had acquired the name that would prove famous: "Mosquito". The prototype was delivered to the Aircraft & Armament Experimental Establishment at Boscombe Down in early 1941. Service trials showed the aircraft to be highly satisfactory and in no need of major design changes.

In July 1941, the initial order for 50 Mosquitos was further modified, with nine of the orders for reconnaissance machines switched to bomber variants, the Air Ministry having become more somewhat more comfortable with the fast bomber concept. Britain was unavoidably in the mode of responding to the hottest fire of the moment for the time being, which inevitably led to confusion and delays in the Mosquito development program.

Along with the shuffling between reconnaissance, fighter, and bomber variants of the Mosquito, the Royal Navy had muddied the waters further by lobbying to get their share of DH.98 production, for use as a fast target tug. After substantial frustration on the part of all concerned, Lord Beaverbrook was able to put a stake through the idea by replying that using an aircraft with twin Merlins as a target tug was a gross waste of precious engine production. The Royal Navy gave in, but remained interested in the Mosquito.

BACK_TO_TOP* Although the Mosquito was extensively modified and updated in production, its basic configuration would always remain very much like that of the initial prototypes. It made use of the wooden construction techniques of the Albatross, with a number of refinements. The two wing spars were made of spruce, with spruce stringers and two-layer birch plywood skinning, not spruce planking as with the Albatross. The spars were laminates, using modest-size pieces to ensure that large trees wouldn't be required, and formed under heat and pressure. The wing was built as a single assembly, covered with fabric, and painted.

The Mosquito's fuselage, like that of the Albatross, was made of a sandwich of balsa between exterior layers of plywood about two millimeters thick, wrapped around seven bulkheads built as a sandwich of spruce blocks between plywood layers. Spruce was used in the fuselage where greater strength was needed, for example around doors or in the wing roots. The fuselage was built in halves, split lengthwise vertically, with the halves formed around male molds and the assembly held together by steel straps while the glue dried.

The split fuselage scheme allowed critical systems to be installed before the two halves were bonded together. That reduced the need for workers to crawl around in the fuselage and sped up assembly, though getting the halves to fit was something of a chore for early prototypes. However, work crews claimed that modifying the airframe was not difficult, the only tool required being a saw. Once fitted together, the fuselage was covered with fabric and painted. The fuselage was sawed out to allow fit of the wing, with part of the sawed-out piece replaced after wing installation. Holes for doors were also sawed out of the fuselage.

The glue and wood construction not only led to light weight, elegant lines, and reduced demand for strategic materials, but also minimized demands on production tooling, meaning that subassemblies could be and were built by such firms as furniture and piano manufacturers. The modular design of the machine also helped support distributed production, with various subcontractors providing subassemblies that could be integrated in the factory.

There were potential drawbacks. The casein glues were strong, but there were worries that they weren't up to high temperature, high humidity tropical conditions found in South Asia -- and so Mosquitos sent there might come "unglued". There were in fact some structural failures of Mosquitos in the Far East, but it is possible they were blamed on the glues simply because they were a convenient culprit. In any case, the casein glues were completely replaced by synthetics, and the problem was declared solved.

Except for the flaps, which were made of fabric over wood frames, the framework for the flight control surfaces was made of light alloy, with metal skinning on the ailerons, fabric on the tail surface, and wood on the flaps.

The prototype had leading-edge slats, but they were deleted in production aircraft, since the machine had proven to have reasonable low-speed handling characteristics. Takeoff performance was improved by flaps, with an inboard and outboard flap on each wing, split by the engine nacelle. The prototype and early production aircraft had shorter nacelles and a single long flap, but buffeting problems led to the extension of the nacelles and the split flap scheme in all later production.

The twin Merlin engines, which drove three-bladed variable-pitch propellers, were mounted on welded steel-tube frames inside low-drag nacelles, with the radiators fitted into the wing between the fuselage and the nacelles. The presence of the radiator extended the wing section that contained it forward of the rest of the wing, resulting in a distinctive "step" in the wing outline when the aircraft was seen from above.

Incidentally, most or all Mosquito variants did not use "handed" engines -- that is, both the left and right propellers turned the same direction, since the same models of engines were used on both sides. Surprisingly, this did not seem to cause much trouble in handling. Some late-mark Mosquitos did use different models of engines on each side, but it appears that the difference was that one had a pneumatic compressor and the other did not.

The Mosquito had tailwheel landing gear, with the main gear retracting backwards into the nacelles, and a retractable tailwheel without tailwheel doors. The main gear featured twin shock struts, filled with rubber blocks, which was simple, cheap, and reliable, if a bit stiff.

The pilot and crewman sat side-by-side, with the pilot's seat on the right and the crewman's seat slightly staggered back. In the reconnaissance and bomber versions, the crewman could crawl forward to a prone bombardier's position in the glass nose. The greenhouse-style cockpit was set forward of the leading edge of the wing and provided an excellent forward field of view, except for the obstruction of the engine nacelles. The rearward field of view wasn't so good; some of the later reconnaissance variants had a transparent bubble on top of the greenhouse, allowing a navigator to stick his head up and take sightings, and also check the "6:00" position for troublemakers.

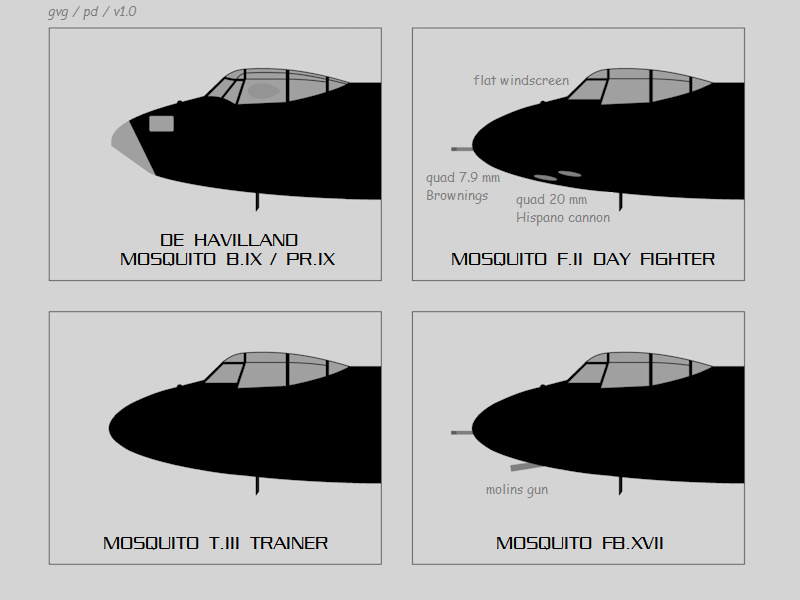

Fighter versions had a flat forward windscreen, which increased drag relative to bomber and reconnaissance variants but improved aiming. Bomber and reconnaissance versions had blisters on the side window panels to give a downward view; these blisters were not fitted to fighter variants.

BACK_TO_TOP* The Mosquito was built in a large number of variants, including:

* The first production examples of the Mosquito were photo-reconnaissance machines. The prototype for the "Mosquito Photo-Reconnaissance Mark I (PR.I)", with the tailcode "W4051", performed its initial flight on 10 June 1941. Despite the fact that the original Mosquito prototype was W4050, the PR.I prototype was actually the third Mosquito prototype to fly, being preceded by the prototype "F.II" version, discussed later.

W4051 was fitted with Merlin 21 engines with 1,090 kW (1,460 HP) each. The aircraft had longer wings than W4050, with the span extended by 50 centimeters (20 inches), though W4051 and the production PR.Is retained the short engine nacelles. The PR.I looked very much like a Mosquito bomber variant, retaining the glass nose for camera targeting and the bomb bay doors, but it included five camera ports. There was a port for an F24 oblique camera behind and below the wing, and twin ports for an F52 stereo camera pair behind the bomb bay doors. There was a port in the front of each bomb bay door, with the bomb bay accommodating either an F24 stereo camera pair or a single K17 camera. The cameras were fitted on steel mounts, but this arrangement was later switched to wooden mounts to reduce vibration.

A total of ten Mosquito PR.Is was completed, including the prototype, which was brought up to production standards. They were all painted blue-gray overall, a color scheme that had been evaluated on Spitfire reconnaissance machines and which was believed a good scheme for high-altitude reconnaissance. The Mosquito was introduced into RAF service with the Number 1 Photo-Reconnaissance Unit (PRU) at RAF Benson, with a PR.I delivered by Geoffrey de Havilland JR on 13 July 1941. Four more were delivered over the next two months, and the type performed its first sorties in September 1941. By the middle of 1942, photo-reconnaissance Mosquitos were sweeping over Europe with little interference, ranging as far as Czechoslovakia and northern Norway.

The PR.I proved so useful that 29 Mosquito B.IV bombers (discussed later) were modified to the PR.I reconnaissance fit and designated "PR.IV". They had increased fuel capacity, with tanks filling up the bomb bay, raising the total internal fuel load from 2,450 liters (540 imperial gallons / 646 US gallons) to 3,180 liters (700 imperial gallons / 839 US gallons). Some of the PR.Is were also fitted with additional fuel tanks.

* Although Rolls-Royce was working on a new engine, the Griffon, in 1941 the RAF had issued an urgent request for a high-altitude engine. Since the Griffon wouldn't be available in the near term, Rolls-Royce began development of the new "Merlin 61" series engines, with two-stage supercharging and 1,255 kW (1,680 HP). The two-stage Merlin 61 proved to be the right thing at the right time, since the RAF's Spitfire Vs were finding themselves outclassed by the Focke-Wulf Fw 190, and the new engine variant was hastily fitted to the Spitfire V airframe to create the more potent Spitfire IX. It was also fitted to the US P-51 Mustang, replacing the P-51's original Allison V-1710 engine to create the much more capable P-51B.

DH was quick to evaluate the new version of the engine on the Mosquito. The first Mosquito prototype, W4050, was refitted with Merlin 61s and put through flight tests, which proved an outstanding success. In June 1942, on its second flight in this configuration, W4050 reached an altitude of 12,200 meters (40,000 feet). The Merlin 61s gave the machine a top speed of 695 KPH (432 MPH) at altitude, a good 80 KPH (50 MPH) faster than the B.IV. W4050 was later refitted with two-stage Merlin 71 engines with 1,275 kW (1,710 HP) each and reached a top speed of 704 KPH (437 MPH), making it the fastest Mosquito ever. Incidentally, W4050 is now on display at Salisbury Hall.

* As the Merlin 61 became available in production quantity, new Mosquito variants were introduced to take advantage of it. Five B.IVs were refitted with the Merlin 61 and converted to a reconnaissance standard as "PR.VIIIs", with initial delivery in January 1943, but that was an interim solution. The first production reconnaissance variant of the Mosquito with two-stage Merlin engines was the "PR.IX", which was introduced in parallel with a similar bomber variant, the "B.IX", discussed later. The first two PR.IXs were delivered to Number 540 Squadron in April 1943, and a total of 90 PR.IXs was built.

The PR.IX was powered by the Merlin 72, with 1,255 kW (1,680 HP). The new engine fit required modified nacelles. While the prop spinners in earlier marks were flush to the nacelles, the PR.IX's nacelles featured a distinctive "chin" intake for the supercharger intercooler, as well as a larger carburetor intake under the nacelle, and six exhaust stacks instead of the five of earlier variants. Exhaust shrouds were not normally fitted.

The PR.IX was also fitted with a new "universal" wing that permitted carriage of the original 227-liter (50 Imperial gallon / 59 US gallon) tanks; or new 454-liter (100 Imperial gallon / 118 US gallon) tanks; or a 225-kilogram (500-pound) bomb, with one store under each wing. The PR.IX rarely if ever carried bombs, but the big wing tanks helped significantly stretch range, to a maximum of 3,945 kilometers (2,450 miles).

In early 1943, the RAF began to evaluate US-made M46 photoflash bombs, which were much brighter than British photoflash bombs. The M46 went into operational service with the PR.IX in the spring of 1943, and did much to increase the effectiveness of Mosquito night reconnaissance.

Eight PR.IXs were refitted with uprated Merlin 76/77 engines and American-designed Hamilton Standard four-bladed paddle propellers. The four-bladed propellers provided improved high-altitude performance, at the expense of poorer low-altitude performance.

* A B.IV was refitted with Merlin 72 engines and cabin pressurization, first flying in July 1943, to become the prototype for the "PR.XVI" and "B.XVI", which like the PR.IX and B.IX were built in parallel. The PR.XVI introduced the canopy top blister for the navigator. A total of 432 PR.XVIs was built.

The RAF decided to use the pressurized PR.XVI as the basis for a specialized high-altitude reconnaissance variant, and modified one to serve as the prototype "PR.32", the RAF having decided to give up on classy but cumbersome Roman numerals and adopt Arabic numbers instead. The PR.32 featured the long-span wing developed for the NF.XV, discussed later, and two-stage "Merlin 113/114" engines optimized for high-altitude operation. Everything that could be removed to lighten the aircraft was taken out.

Five production PR.32s followed. They were used in the last months of the war in Europe, operating at altitudes of 12,800 meters (42,000 feet).

* The last production Mosquito reconnaissance variant, the "PR.34", was essentially a PR.XVI with bulged bomb bay doors to accommodate long-range fuel tanks.

___________________________________________________________________

DE HAVILLAND MOSQUITO PR.34:

___________________________________________________________________

wingspan:

16.51 meters (54 feet 2 inches)

wing area:

33.54 sq_meters (361 sq_feet)

length:

12.65 meters (41 feet 6 inches)

height:

4.65 meters (15 feet 3 inches)

empty weight:

7,545 kilograms (16,630 pounds)

max loaded weight:

11,565 kilograms (25,500 pounds)

maximum speed:

685 KPH (425 MPH / 370 KT)

service ceiling:

13,100 meters (43,000 feet)

range:

5,375 kilometers (3,340 MI / 2,905 NMI)

___________________________________________________________________

181 PR.34s were built, with 50 of these produced by Percival. The PR.34 was intended for service in the Far East, and a number were deployed to the theater before the end of the war in the Pacific in August 1945. The PR.34 was apparently something of a handful to get off the ground with fully loaded tanks. It was the heaviest of all the Mosquitos, with a maximum take-off weight about 35% greater than had been ever expected when W4050 took to the air.

* Ten "B.35s", described later, were converted to a reconnaissance configuration and redesignated "PR.35". These machines did not reach operational service until after World War II.

BACK_TO_TOP* When the Mosquito was being designed, the DH engineering team made sure provision for fixed gun armament was included in the design, on the assumption that people would come around to the idea of using the machine as a fighter. They were proven right.

The second Mosquito prototype to fly, "W4052", was originally fitted out as a long-range fighter, the "F.II". It was armed with four 7.7-millimeter (0.303-caliber) Browning machine guns in the nose and four 20-millimeter Hispano Mark II cannon in a ventral tray. The guns were all belt-fed and actuated electro-pneumatically, driven by a compressor in the left engine nacelle. The compressor also drove the pneumatic wheel brakes. The clustering of the guns meant the pilot had to be a good shot, but in compensation they also had terrific focus, and once on a target, they usually made short work of it.

Although reconnaissance and bomber versions of the Mosquito had a hatch on the bottom of the left side of the nose for crew entry, the armament blocked entry by that route in the F.II, and so all fighter versions featured a door on the right side of the fuselage forward of the wing. The fighter's wing spars were also reinforced to permit more aggressive maneuvers; armor glass was fitted in the (flat) windscreen; and the pilot flew using a stick, instead of the yoke used in the reconnaissance and bomber variants.

W4052 performed its initial flight on 15 May 1941, with Geoffrey de Havilland JR at the controls. The machine was flown from a field next to Salisbury Hall, to save the time needed to break it down, transport it to Hatfield, and reassembled again. The field was a bit on the short side, but de Havilland negotiated with the farmer who owned the adjoining property for the removal of some hedges that blocked the way.

Just before dawn on 13 May, an SS officer named Karl Richter parachuted into England, landing not far from Salisbury Hall. It appears he did not know the significance of the manor and both his landing spot and timing were coincidental, since he was trying to make his way into London when he was arrested the next day. Although many of the German agents the British had captured ended up working for the Allied cause (in some cases with surprising enthusiasm) under the "Double Cross" system to feed back false information to German intelligence, Richter was uncooperative. He was hanged on 10 December 1941.

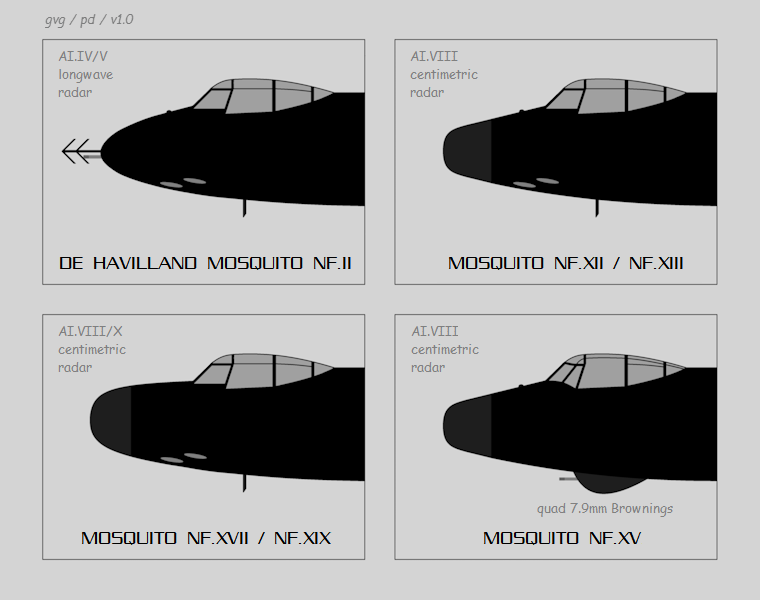

* With the shift of the Luftwaffe to night raids in the fall of 1940, the priority of the moment switched to night fighters, and in the summer of 1941 W4052 was fitted with longwave "airborne intercept Mark IV (AI.IV)" radar. The success of this fit led to the "Night Fighter Mark II (NF.II)". It featured the same armament as the F.II, but was painted black and had an arrow-shaped arrowhead-shaped transmit antenna in the nose for the AI.IV radar, and dipole receive antennas mounted through the wingtips.

The NF.II went into operational service with RAF Number 151 & 157 Squadrons in early 1942, replacing the sturdy but relatively slow Bristol Beaufighter. They scored their first kills that spring. A total of 494 F.IIs and NF.IIs was built. It is unclear what the proportions of day fighters and night fighters were, but it appears that most were built as night fighters. The NF.II was rushed into service so fast that there were some surprises for flight crews that should have otherwise been caught in test and evaluation, such as the fact that firing the 7.7-millimeter guns wiped out the pilot's night vision. The guns were refitted with cone-shaped muzzle flash suppressors in the field, with this item rolled into production.

Apparently most NF.IIs were fitted with "AI.V" radar, which was generally similar to AI.IV but included a cockpit panel display for the pilot that helped the radar operator direct him to a target. The radar was classified as top secret and NF.IIs carrying it were not allowed to fly over Occupied Europe, but beginning in mid-1942, about 25 NF.IIs had their radar removed and were fitted with additional fuel tanks for night intruder operations. They would fly over the Channel to lurk around Luftwaffe airfields and pounce on German aircraft flying with their landing lights on. These Mosquitos were redesignated "NF.II (Special)".

One NF.II was fitted with a "Turbinlite" searchlight in the nose for night fighting, but trials showed the scheme to be ineffective. A few F.IIs were built with dual controls, becoming the basis for the "Trainer Mark III (T.III)", most of which were unarmed, except for some that retained their guns for weapons training. The first T.IIIs were built in 1943, though most production would take place after the war, with a total of 358 built, including six conversions from F.IIs.

* The AI.V radar was workable but had limited accuracy and range, as well as a long minimum range that meant the NF.II's crew would lose radar contact before the pilot could actually see the target. New "centimetric" (microwave) radars that were much more capable soon became available, and an NF.II was refitted by Marshalls at Cambridge with "AI.VIII" centimetric radar in the summer of 1942.

The AI.VIII had a modern radar dish accommodated in a "thimble" radome on the night fighter's nose, which meant deletion of the four 7.7-millimeter Brownings. The new radar fit worked very well, and so 97 more NF.IIs were converted to the same standard during the first half of 1943, and redesignated "NF.XII". The type scored its first kill in February 1943.

The NF.XII led in late 1943 to the "NF.XIII", which was essentially a production version of the NF.XII, modified from an "FB.VI" fighter-bomber version of the Mosquito, discussed later, by fitting AI.VIII radar. The NF.XIII inherited wing attachments for 227-liter (50 Imperial gallon / 57 US gallon) "slipper" tanks from the FB.VI, giving the night-fighter the range to accompany RAF bomber streams over Occupied Europe to take on German night fighters. 260 NF.XIIIs were built.

In the meantime, the Americans were beginning production of their "SCR-720" radar, arguably the best AI set of the war, and the British adopted it as the "AI.X". Marshalls modified 99 more NF.IIs to a night-fighter configuration, this time with the AI.X radar, resulting in the "NF.XVII".

That of course led to production of an enhanced version of the NF.XIII with the AI.X radar, designated the "NF.XIX". It had a "bullnose" radome that could accommodate either an AI.VIII or AI.X radar, as radar deliveries permitted. The NF.XIX also had Merlin 25 engines with greater low altitude power. Initial flight was in April 1944, with 280 built.

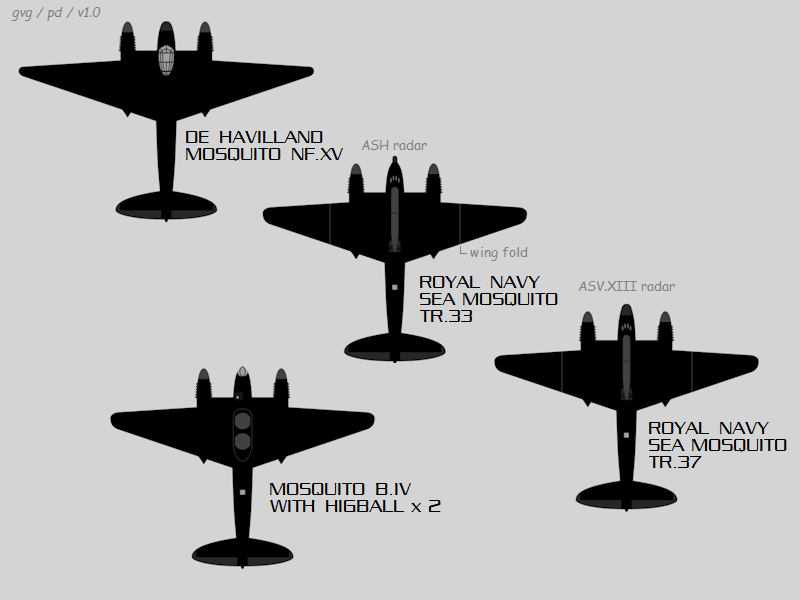

* Following high-altitude incursions over Britain by pressurized Luftwaffe Junkers Ju 86 bombers, five Mosquito "NF.XVs" were built as high-altitude night fighters. DH workers were particularly keen on getting these aircraft to work, since the Ju 86s had been occasionally overflying the Hatfield plant.

The NF.XVs were based on the B.IV and retained the bomber-style canopy, but featured two-stage Merlin 73 engines, wingtip extensions, and pressurized cabins. As much gear as possible was removed to reduce the weight of the aircraft. The Hispano cannon were removed and replaced with a lighter belly pack of four 7.7-millimeter guns. That armament was regarded as sufficient to deal with the Ju 86, which lacked armament and armor, using used height as its only defense.

The NF.XVs were fitted with AI.VIII radar in a thimble radome. By the time the NF.XVs were in service, the Germans had largely given up on high-altitude overflights. The NF.XVs were mostly assigned to test and evaluation duties for pressurization systems,

* The last Mosquito night-fighter version to see significant combat service was the "NF.30", which was similar to the NF.XIII, but had two-stage Merlin engines, either Merlin 72s or 76s, and AI.X radar in a bullnose radome. Initial flight of the NF.30 prototype was in March 1944, with the type entering operational service in June and performing its first kills in August. There were operational teething problems with the exhaust shrouds that led to a new louvered shroud design. 526 NF.30s were built.

The Mosquito night-fighter served on in the postwar period as an interim solution until the arrival of jet-powered night fighters. Two Mosquito night-fighter variants were produced after the war, including the "NF.36" and the "NF.38". The NF.36 was similar to the NF.30, but had Merlin 113 engines and a "bullnose" radome. Initial flight was in May 1945 and 163 were built into 1947, with some of them put into service for weather reconnaissance. The NF.38 was basically an NF.36 with Merlin 114A engines and AI.IX radar, which the British had continued to work on after the war. Following conversion of a single NF.36 as a prototype, 101 NF.38s were built. The NF.38 was the last Mosquito variant to be produced, with the final example rolled out in 1950.

The NF.38 was also one of the least successful variants. AI.IX was wasted effort, not a match for AI.X and substantially heavier. The new engines and the heavier radar made the aircraft unpleasantly nose-heavy and troublesome to fly. Ironically, the NF.38 never entered RAF service, with 54 supplied to Yugoslavia and the rest scrapped.

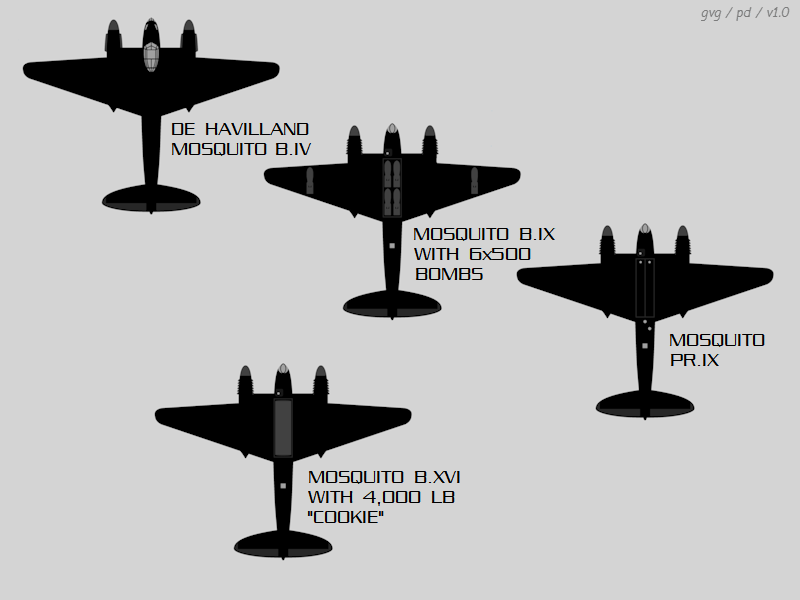

BACK_TO_TOP* The initial Mosquito bomber variants were based on the PR.I. The nine Mosquitos diverted from PR.I production to be completed as bombers became "Bomber Mark IV (B.IV) Series I" machines. They were much like the PR.I, with a glass nose, no gun armament, and short engine nacelles, but had no camera ports.

They were followed by the "B.IV Series II", with 263 built. These machines had the longer nacelles, as well as shrouded exhausts to hide the exhaust flames for night operations. They also had wing attachment points for the 50 Imperial gallon slipper tanks mentioned earlier, though it is unclear if this was included in production from the outset. Later B.IV Series II machines would have exhausts modified to provide a slight jet effect to improve the aircraft's performance by about 16 KPH (10 MPH), improving its speed advantage over the German Focke-Wulf Fw 190.

The B.IV had a glass nose for a bombardier and no gun armament. The Mosquito had been designed to carry four 112-kilogram (250-pound) bombs, but the bomb load was limited simply by space and not lifting capacity. In the fall of 1941 consideration was given to carriage of four 225-kilogram (500-pound) bombs. The bomb tailfin span had to be cut down to allow a fit, but tests performed at Boscombe Down with the Mark V showed that the smaller tailfins did not affect stability, and the new tailfins were incorporated into bomber production.

The first B.IV Series I was delivered to RAF Bomber Command Squadron Number 105 on 15 November 1941, with Geoffrey de Havilland JR at the controls. The first B.IV Series II was delivered in May 1942, and the first strikes were performed at the end of the month.

___________________________________________________________________

DE HAVILLAND MOSQUITO B.IV SERIES II:

___________________________________________________________________

wingspan:

16.51 meters (54 feet 2 inches)

wing area:

33.54 sq_meters (361 sq_feet)

length:

12.43 meters (40 feet 10 inches)

height:

4.65 meters (15 feet 3 inches)

empty weight:

5,942 kilograms (13,100 pounds)

max loaded weight:

10,150 kilograms (22.380 pounds)

maximum speed:

612 KPH (380 MPH / 330 KT)

service ceiling:

9,450 meters (31,000 feet)

range:

1,965 kilometers (1,220 MI / 1,060 NMI)

___________________________________________________________________

Although initially employed in bombing attacks, Bomber Command decided that the best use of the Mosquito bomber was for "pathfinding", marking targets with huge flares that other bombers would use as an aim point. B.IVs were fitted with the latest electronic navigation aids, including "Oboe" and "H2S", which are discussed later, to help them find their way to targets at night and in overcast weather.

With the B.IV in service as a pathfinder, Bomber Command then gradually began to use the machine for nuisance attacks, arriving at the conclusion that it would be an even greater nuisance if it could carry a much bigger bomb. Beginning in April 1943, a B.IV was modified with bulged bomb-bay doors to allow it to carry a single 1,815-kilogram (4,000-pound) "High Capacity (HC)" bomb, known as a "Cookie", little more than a very big thin-shelled can full of explosives and with no fins. The modified B.IV also featured nose ballast, reduced fuel tankage, and modified elevators. The scheme proved workable, and 22 more B.IVs were modified to this specification, beginning operations in early 1944. They were sometimes referred to as "B.IV (Specials)".

Surprisingly, apparently even to the people involved at the time, the heavily-loaded Mosquito had little problem getting off the runway, though not so surprisingly Mosquito bomber variants with two-stage engines were more comfortable with the load. In any case, if the aircraft lost an engine, the crew needed to get rid of the Cookie as fast as possible. Crews sometimes called it the "Dangerous Dustbin", presumably meaning dangerous to themselves as well as the enemy.

60 B.IVs were also modified to carry the "Highball" anti-ship bomb, an unusual weapon that is also described in more detail later.

* Although a single "B.V" was built, it didn't go into production. As mentioned earlier, availability of the new two-stage Merlin engines led to the next production bomber variant, the "B.IX", equivalent to the PR.IX with Merlin 72 engines and the universal wing. The first production machine performed its initial flight on 24 March 1943, with the first service delivery to Number 109 Squadron on 21 April 1943. 54 B.IXs were built in all.

With four 225-kilogram (500-pound) bombs in the bomb bay and a 225-kilogram bomb under each wing, the B.IX normally had a maximum bombload of 1,350 kilograms (3,000 pounds). Some of the B.IXs were fitted with bulged bomb bay doors to carry a Cookie bomb. The B.IX was generally used for Pathfinder duties.

The last Mosquito bomber variant to see wide service was the "B.XVI", which was generally similar to the B.IX but had a pressurized cabin. 402 were built, with all but the first 12 fitted with the bulged bomb bay doors for Cookie carriage.

The final Mosquito bomber variant produced was the "B.35", which was very similar to the B.XVI with the bulged bomb bay doors, but had uprated Merlin 114 engines with 1,275 kW (1,710 HP) each, and was fitted with a "Gee-H" radio navigation system. The Gee-H fit featured three distinctive dipole antennas fitted vertically through each wingtip. First flight of the B.35 prototype was on 12 March 1945, though they didn't reach RAF operational service until 1948. A total of 265 was built.

BACK_TO_TOP* The most versatile, and most heavily produced, of all Mosquito versions were the fighter-bomber variants. A total of 2,584 "FB.VIs" was built, featuring four 7.7-millimeter machine guns in the nose and four 20-millimeter cannon in the belly, with a small bomb bay added behind the cannon tray to carry two 112-kilogram (250-pound) or, in practice, two 225-kilogram (500-pound) bombs.

Two external hardpoints, one under each wing, could be used to carry two slipper tanks or two more bombs. The wings were reinforced to help handle the loads. Not long after its operational introduction, the FB.VI was given another armament option, underwing racks for 7.62-centimeter (3-inch) diameter solid-fuel rocket projectiles (RP). The RP could be fitted with high explosive, hollow charge, or incendiary warheads and proved very effective for ground and anti-ship attack.

Initial flight of a prototype FB.VI was in July 1942, but the aircraft met with an accident. Other delays stretched rollout of the first production FB.VI to February 1943, with Number 418 Squadron of RAF Fighter Command accepting their first FB.VI in May of that year, and Number 605 Squadron following in July. These two squadrons performed intruder attacks over occupied Europe. The FB.VI was also used in the fighter-bomber role against the Japanese in Burma.

___________________________________________________________________

DE HAVILLAND MOSQUITO FB.VI:

___________________________________________________________________

wingspan:

16.51 meters (54 feet 2 inches)

wing area:

33.54 sq_meters (361 sq_feet)

length:

12.47 meters (40 feet 11 inches)

height:

4.65 meters (15 feet 3 inches)

empty weight:

6,485 kilograms (14,300 pounds)

max loaded weight:

10,115 kilograms (22,300 pounds)

maximum speed:

585 KPH (360 MPH / 315 KT)

service ceiling:

10,000 meters (33,000 feet)

range:

2,655 kilometers (1,650 MI / 1,435 NMI)

___________________________________________________________________

* RAF Coastal Command obtained a specialized derivative of the FB.VI, the "FB.XVIII", which had a 57-millimeter autoloading Molins gun, an airborne modification of the light 6-pounder anti-tank gun, installed in place of the four 20-millimeter cannon. Two of the 7.7-millimeter Brownings were often removed in the field, with the two remaining used for sighting the big gun.

The Molins gun was adopted to help Mosquitos hit German submarines from out of range of the vessel's antiaircraft guns and proved effective, but Coastal Command Mosquitos were then qualified to carry a variant of the RP with a solid warhead. Aircrews felt the RP was a much better weapon. 25 FB.XVIIIs were built, all as conversions of FB.VIs, with the first flying in mid-1943.

* Interestingly, all the Mosquito FB marks used single-stage Merlins. There were many demands on two-stage Merlin production, and since the fighter-bombers almost always operated at low level, they had no need of improved high-altitude performance. An "FB.XI" with two-stage engines was considered but not built.

BACK_TO_TOP* The Royal Navy's Fleet Air Arm (FAA) operated both FB.VI and T.III Mosquitos from shore bases beginning in 1944, and it was a logical step to then operate the Mosquito off of aircraft carriers. The first truly navalized Mosquito was an FB.VI modified by DH with an arresting hook, pneumatic landing gear struts, a strengthened fuselage, and four-blade paddle propellers. It began trials on board the HMS INDEFATIGABLE on 25 March 1944, and was the first British twin-engine aircraft to land on a carrier. The trials were successful, and another FB.VI was converted to an improved navalized configuration, adding folding wings and a nose radome.

These two prototypes led to the production Mosquito "Torpedo Reconnaissance 33 (TR.33)", with the initial TR.33 performing its first flight on 10 November 1945, after the end of the war. The FAA ordered 97, but with postwar cutbacks, the total buy was cut to 50. The first 23 TR.33s had nonfolding wings and conventional Mosquito landing gear, but the remainder had folding wings and reinforced landing gear. The TR.33 had the four 20-millimeter cannon but no machine guns, with the nose fitted with a small "thimble" radome containing US ASH (AN/APS-6) three-centimeter radar.

The TR.33 could carry two 225-kilogram (500-pound) bombs in its bomb bay or a single 46-centimeter (18-inch) torpedo slung under the fuselage, while different configurations of external tanks, rockets, or bombs could be carried under the wing. With two 227-liter (60 US gallon) external tanks, the TR.33 had a range of 2,415 kilometers (1,500 miles). The aircraft could be fitted with "rocket assisted take-off gear (RATOG)", with a RATOG bottle on each side of the rear fuselage, for shorter take-offs under heavily loaded conditions.

The TR.33 entered service with FAA Number 811 Squadron in August 1946, but the Sea Mosquito's service life was very short, with the squadron disbanded in July 1947 and the aircraft put to second-line duties. None of these machines ever served operationally on an aircraft carrier.

The FAA also obtained fourteen "TR.37 Sea Mosquitos", which were almost identical to the TR.33, except for a much bigger radome somewhat like that of the NF.30, to accommodate British "ASV Mark XIII" radar instead of ASH radar. The service life of the TR.37 was short as well.

* Well over 7,000 Mosquitos were built from 1941 to 1950, with most British production from DH at Hatfield and also the company's plant at Leavesden. Standard Motors also built the Mosquito in quantity, and small numbers were built by Percival and Airspeed. Canadian and Australian production is detailed in the next chapter.

BACK_TO_TOP