* The DC-3 was also built under license by other nations, including the Soviet Union -- as the "Lisunov L2D" -- and surprisingly Japan -- as the "Showa L2D". In addition, Douglas built a bomber derivative, the "B-18 Bolo", which led to the improved "B-23 Dragon".

* The Soviets were particularly enthusiastic about the DC-3, building a large number of them under license. In 1935, a delegation led by well-known aviation designer Andrei N. Tupolev arrived in the USA to purchase a DC-2 and other American aircraft for possible license construction. Arrangements were made, and later in 1935 AMTORG, the Soviet trade organization in the USA, bought one DC-2, which was flown to the USSR and minutely inspected.

Soviet engineers were impressed with the aircraft's standard of quality. Interest was keen in obtaining the follow-on DC-3 as well, and in fact the Soviets decided to go ahead and obtain a production license for the type. A number of engineers went to the USA from the late summer of 1936 to work on the effort, including Boris P. Lisunov, Anatoliy A. Senkov, and Vladimir M. Myasishchev; Myasishchev would later have his own aircraft design bureau.

The program started with an initial buy of 18 DC-3s from Douglas. These machines were built to Soviet spec and were designated "DC-3-196"; they were delivered from late 1936 into 1939 through AMTORG dummy front companies, apparently to prevent the US government from becoming worried that the Soviets might use the machines for military purposes. Tooling for production at State Factory Number 84 in Khimki was ramped up in the meantime, with plans converted from English to metric measurements obtained from Douglas.

The production facility was under the direction of Myasishchev until 1938, when an aircraft prototype he had designed crashed. Failures to deliver the goods in Stalin's USSR were often judged "treason", and he was arrested. Traveling abroad was a cause for suspicion, the idea being that anyone who had done so might have been recruited as an agent by an enemy power, and Myasishchev ended up in the prison camp system for the time being. Senkov took over the plant; Lisunov was chief engineer.

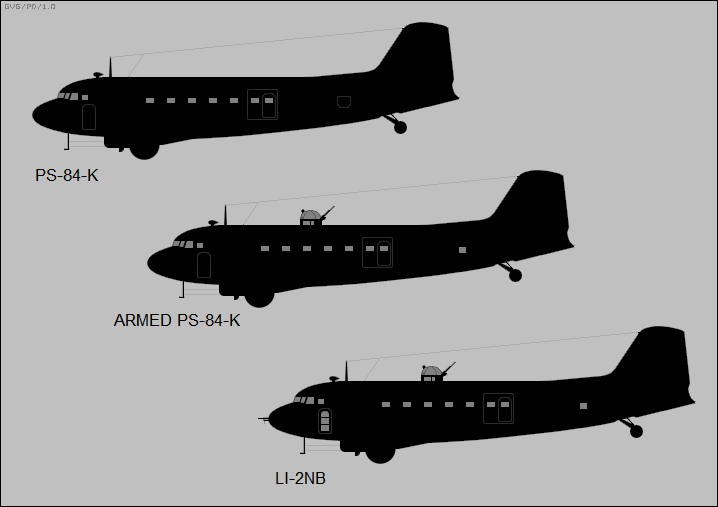

In any case, the first Soviet-built DC-3 was rolled out in November 1938. It featured Shvetsov M-621R radials, which were Soviet-built derivatives of the Wright Cyclone, with the aircraft designated "DC-3 2M-621" and then "PS-84" -- the last just meaning "passenger aircraft from Plant 84". It went into state trials, completing evaluation in December 1939. There were some bureaucratic difficulties in getting production ramped up, but by the end of 1940, dozens of PS-84s had been built, to go into service with Aeroflot, the state airline. Incidentally, Aeroflot also operated some of the DC-3s obtained directly from Douglas.

The PS-84 was not an identical copy of the DC-3. It was built to higher levels of strength and a lower level of refinement -- both in accordance with typical Soviet design and manufacturing processes -- and leveraged off Soviet subassemblies where possible. It was most visibly different in that the DC-3 had the passenger door on the left, opening out and forward, while the PS-84 conformed to Soviet practice with the door fitted on the right, opening inward and aft. None were ever built with astrodomes.

The engine cowlings were also subtly different from those of the C-47, and could be fitted with an odd two-level front cowling plate featuring radial slots. The cowling plate could be shifted so that the slots were open or closed. The plate was for cold climates, but its usage remains a bit unclear; the slots were apparently closed by the ground crew after landing to protect the engine from ice and snow, then opened again before firing up the engines. One suspects it was locked in either the open or closed position, since it would have been troublesome for the slots to vibrate shut during flight. It is also unclear if the plate was in halves, so it could be fitted or pulled off without removing the propeller.

Initial passenger seating arrangement was 14 seats, with seven rows of two seats, quickly increased to 21 seats, with seven rows of three seats. The PS-84 retained the DC-3's good handling characteristics and Aeroflot pilots liked it, particularly praising its engine-out capabilities.

By the time Nazi Germany invaded the USSR on 22 June 1941, 237 PS-84s had been built at Plant 84, all in civil passenger configuration. In response to the invasion, the Kremlin set in motion a plan of astounding scope to relocate much of the industrial capability of the Soviet Union to the East, with Plant 84 ending up at Tashkent, now the capital of Uzbekistan. After a monumental struggle, Plant 84 was rolling out PS-84s again by January 1942.

BACK_TO_TOP* There had been considerations of what else might be done with the PS-84 before the German invasion, with concepts drawn up of machines with various powerplants, including liquid-cooled and diesel engines; a staff transport; a "gunship" version, to be armed with an array of heavy cannon and machine guns; and a bomber version. The only option that was seriously investigated in this timeframe was to modify the PS-84 to create a machine that could be easily converted in the field between passenger, troop carrier, cargolifter, or medevac configurations. A prototype of the "PS-84-K", as this convertible variant was known, was converted from an early production PS-84, but this machine performed a crash landing in bad weather in January 1940 and had to be written off. A second prototype was put together and state trials began in the spring.

The PS-84-K's most prominent feature was a large cargo door that opened upward and outward on the left side of the rear fuselage; a paratroop door that opened inward and upward was embedded in the cargo door. The regular door on the other side of the fuselage was retained. The floor was reinforced to handle cargo, and a crane was fitted behind the cargo door to simplify loading and unloading of freight. 27 tip-up seats could be installed along the walls for passenger carriage.

The PS-84-K could be configured as a paratroop transport by setting up two rows of benches back-to-back along the centerline installing static parachute release lines. 24 fully-equipped paratroops could be carried. The aircraft could also be configured for the medevac role, fitted with eighteen stretchers -- a row of nine along each wall of the fuselage, with the rows in tiers of three. Two walking wounded and a medical attendant could be accommodated on tip-up seats. When configured for the medevac mission the machine was designated the "PS-84-I"; once the medevac kit was yanked, it was just a plain PS-84-K again.

* After passing trials, the PS-84-K was recommended for production, but it didn't happen. It would have meant modifying the production line, and the PS-84-K was more complicated to build. Given the pressures of events, nobody wanted to interrupt or slow down production, and so the PS-84 was modified to a compromise multirole configuration -- with the cargo door, but no crane and no strengthened floor. The machine could be fitted with 25 tip-up seats or set up for medevac operation.

The German invasion was staggeringly successful at first, and the Soviets would not completely reverse the tide against them until 1943. Aeroflot had been put on a war footing after the invasion and employed its PS-84s for military supply and transport missions. The crews generally had little or no combat training, having only flown commercial routes in the past, but they sometimes conducted themselves heroically under extremely dangerous circumstances. The PS-84s often operated in forward areas where they stood a good chance of being attacked, and they had no defenses. A repair depot came up with a scheme for installing a turret on top of the forward fuselage, as well as a machine gun on a flexible mount at each side of the rear fuselage. The armament fits were varied, depending on what spare turrets and machine guns were at hand.

From July 1941, the existing PS-84 fleet was gradually upgraded to an armed configuration; the armament cut into performance and payload, but it was far better than being helplessly shot down in flames. A few Luftwaffe pilots were shot down when they pounced on an "easy kill", without realizing that it could fight back; their surviving brethren became more cautious in their attacks on the PS-84. By August 1941, new-build PS-84s were rolling off the production line fitted with armament from the start.

The initial armament configuration was an MV-3 turret with a 7.62 millimeter (0.30 caliber) ShKAS machine gun. Armament was quickly improved by adding two DA machine guns of similar caliber in the fuselage positions, as well as a ShKAS gun fitted in a fixed position in the nose -- not surprisingly, the nose gun was almost useless, and was later deleted. The armament was later upgraded to a UTK-1 turret with a UBT 12.7 millimeter (0.50 caliber) machine gun, with the beam positions fitted with ShKAS instead of DA machine guns. Both the ShKAS and DA fired the same 7.62 millimeter round, but the ShKAS had a substantially greater rate of fire. Sometimes additional machine guns were installed in windows in the field.

Given the severity of the military situation in 1942, it wasn't surprising that the PS-84 was thrown into action as an offensive weapon. In the spring of that year, a few PS-84s fitted with belly bomb racks in the field took part in raids on Finland -- operating at night, since they were too vulnerable for daylight attacks. Soviet Premier Josef Stalin personally liked the idea of using the PS-84 as a night bomber, and the appropriate directives went down from the Kremlin to make it happen.

As it emerged, the bomber version of the PS-84 featured the four-gun defensive armament of the military transport variants, with racks for four bombs under the belly. A window for a bombsight was pigeonholed into the baggage loading door on the left side of the nose -- the bomber did not have nose glazing. There were three windows in the door, and the bombardier had to hinge the bottom window out to deploy the bombsight for use.

Bombload was either four FAB-250 250-kilogram (550-pound) general purpose bombs, or two FAB-500 500-kilogram (1,100-pound) general purpose bombs. Sometimes four RRAB-250 250-kilogram cluster bombs were carried instead of FABs. In principle, the bomb racks could also carry two 500-kilogram liquid dispensers -- an odd weapon that could be filled with toxic agents or inflammable liquids. It is unclear if the liquid dispensers were ever used operationally.

Parachute-dropped supply canisters could be carried in place of munitions. The bomber variant could still be used as a transport, and in fact it was really less a bomber and more a multirole machine that could be pressed into various services as the need arose. Other changes included an inert gas system that fed cooled engine exhaust gases into the fuel tanks to reduce battle fire hazard, plus structural reinforcements. There was no improvement in engine power, and so performance degraded again.

The bomber variant was accepted for service in September 1942, to be given the designation "Lisunov 2" or "Li-2". The choice of designation was odd because Boris Lisunov was only one of a number of senior engineers on the project, and arguably not the most prominent of them. However, all the Soviet DC-3s became "Li-2s" from that time on. Following the production of other variants, late-production Li-2 night bombers, with improved kit, were given the designation of "L-2NB" -- where "NB" stood for "nochnoy bombardirovshchik (night bomber)". It is unclear if the Li-2NB designation was retroactively applied to earlier machines in the series.

BACK_TO_TOP* The Li-2 went into active combat service during the Battle of Stalingrad, which began in late 1942, and distinguished itself in action. It wasn't the best weapon, not having been originally designed as to drop bombs, but as long as it kept to night attacks, it did fairly well for itself. As better purpose-built bombers came into service the Li-2s were increasingly returned to use as transports, but they still continued to perform strikes up to the end of the war. The loss rate would ultimately be about a quarter of all of the Li-2s built, which was actually not such a bad loss rate by Soviet standards.

The Li-2 fleet was complemented by C-47s supplied by the USA under the Lend-Lease military assistance program, as mentioned with over 700 Dakotas supplied to the USSR from mid-1942 to the end of the war. Even Russian sources claim that the C-47 was much preferred by aircrews -- it not only had more powerful engines, it was also better built. Although the Soviets liked to build gear that was tough, reliable, and easy to maintain, somewhat surprisingly the C-47 outmatched the Li-2 in all these categories. For example, the time between overhaul of the Li-2's Soviet-made propellers was only 50 hours, while it was 750 hours for the C-47's Hamilton Standard Hydromatic propellers, which were more complicated. An engine change on the C-47 was much easier than it was on the Li-2.

The avionics kit of the C-47 was also far superior, even though the Dakotas supplied to the USSR didn't have full kit, with some mountings left vacant. Very surprisingly, the C-47 was better designed for cold-weather operations: its pneumatic leading-edge de-icer boots were much more effective than the thermal de-icers used on the Li-2, and crews really liked the C-47's heater system -- the Li-2's heater was built around a steam boiler and was nuisance to get to work right. The flight engineer was sometimes referred as the "stoker", since he spent a good amount of time fiddling with it.

Still, the Li-2 was a good machine, inheriting many of the virtues of its American parent, and various improvements were added over time. From the summer of 1943, the engines were fitted with flame dampers -- the lack of which had been an unforgivable weakness for a night bomber. A short time later built-in hoists were added to the bomb racks, making life easier for armorers.

The Red Air Force unsurprisingly did not like the improvised bomb-aimer's position and wanted a glazed nose with armament, but it didn't happen, at least not during the war. The air force also wanted internal bomb carriage to permit better performance if the external racks weren't used, or more bombload if both bombs were carried both internally and externally. An Li-2 was converted carry three internal bomb cassettes -- two behind the cockpit and one in the rear fuselage -- but the modified aircraft flunked its trials. A simplified approach was implemented with the single "Li-2VP", which had twin bomb bays in parallel behind the cabin; it was not accepted into production, the perception being that the benefits did not justify the production change.

* There were a number of special fits and modifications of the Li-2 during the conflict:

* In May 1945, with the war in Europe won, production of the Li-2 reverted back to civil airliner configuration. The "Li-2P", as the revived airliner was called, incorporated the manufacturing improvements acquired during the war, with the armament of course deleted. The cargo door was deleted as well, and the aircraft was fitted with comfortable seating for 24 passengers, along with a toilet, coat closet, and overhead bins. Ten Li-2Ps were modified as VIP transports. An "Li-2T" with the cargo door but no armament was built in parallel for both civil and military use,

Aeroflot had actually been performing civil airliner flights with the Li-2 from late 1944, with full services reestablished by the end of 1945. The Li-2 remained the mainstay of Aeroflot into the mid-1950s, to then gradually phase out of service until being completely retired in 1962. Along with regular airline service, Li-2s operated in a number of other non-military roles:

* Military Li-2s that had survived combat remained in the ranks of the Red Air Force, though there was no thought of ever seriously using them as bombers again. NATO assigned the type the reporting name of "Cab". The Li-2's primary mission was as a paratroop transport, though of course with so many in service it was still useful as a cargolifter. Even though better transports started to replace it in service late in the 1940s, it still remained a valued asset through the 1950s, being particularly useful as a multi-engine trainer, being docile and cheap to operate.

It was also used in specialized training roles. The "UShLi-2" was a navigation trainer -- "Ush" stood for "uchebno-shturmanskiy (Navigation trainer)" -- featuring an "antenna farm" on the back for sets of radio compasses and communications gear, with two rows of "workstations" for trainees inside. The UShLi-2 saw extensive use with the Red Air Force and with the air forces of a number of Soviet client states. A "long nose" radar trainer designated the "Li-2R" was deployed in smaller numbers, and a small number of bombardier / gunner training machines with a dorsal turret mounting a ShKAS 7.62 millimeter machine gun.

A few Li-2s were fitted out for the electronic countermeasures (ECM) and ELINT roles. The Li-2 was also used as a research platform, including sampling of fallout from nuclear tests, and for trials of radar and other gear, in some cases being fitted with the noses of cruise missiles to test guidance systems. The Li-2 was used in the airlift role once again during the occupation of Hungary in 1956. The Li-2 was finally mustered out of the military in 1964, though Li-2s went on to serve in the ranks of the DOSAAF, the youth aviation organization that trained youngsters for later service in Red military aviation.

Li-2s were supplied to Soviet client states, including Warsaw Pact nations and North Korea. Batches were supplied to North Vietnam in the late 1950s and early 1960s. North Vietnamese Li-2s were quickly put to use in military airlift operations into Laos, and served through the war with the Americans. The Li-2 was generally out of service by the mid-1970s, though some "flying museum pieces" remain in the air today.

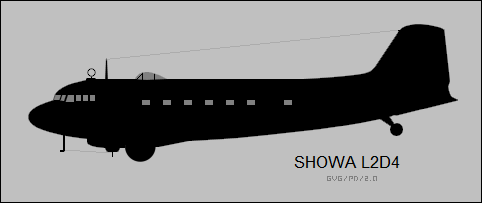

BACK_TO_TOP* Very surprisingly, DC-3s were also built in Japan during the war. Two Japanese trading firms, Mitsui and Far Eastern Trading, bought a total of 20 Douglas-built DC-3s, which went into service with Dai Nippon Air Lines and served through the war.

In 1938, Mitsui went on to obtain a manufacturing license for $90,000 USD in 1938, not bothering to tell Douglas that they were doing so at the request of the Imperial Japanese Navy. Mitsui obtained all specifications, and then also bought two unassembled DC-3s from Douglas as manufacturing pattern machines. Mitsui arranged delivery of the unassembled machines to the Showa company, which was to cooperate with Nakajima for manufacture.

The two unassembled DC-3s were put together by Showa and delivered in October 1939 and April 1940, to be given the designation "L2D1". In the meantime, Showa and Nakajima had been working to modify the design to use 764 kW (1,000 HP) Mitsubishi Kinsei 43 radials in place of the US-built engines. This resulted in the first Japanese production variant, the "L2D2". Nakajima built 71 of this model, delivering the last in November 1942, when the company got out of the business of building DC-3 clones.

However, Showa remained in the trade, and in fact the Imperial Japanese Navy selected the type as their standard transport aircraft. Showa delivered their first L2D2 in March 1941, quickly moving on to improved variants. The "L2D2-1" was a cargo hauler, with a reinforced floor and cargo doors on the left side of the rear fuselage. The "L2D3" was an improved passenger version, with Kinsei 51 radials providing 970 kW (1,300 HP) each and cockpit windows distinctively extended back along the fuselage. An equivalent cargo version, the "L2D3-1", was also built. Both these variants were later built with improved Kinsei 53 engines, also with 970 kW (1,300 HP), and designated "L2D3a" and "L2D3-1a" respectively.

The "L2D4" was an armed variant, with a top gun position mounting a single 13-millimeter gun, and a single 7.9-millimeter gun firing from a hatch on each side of the aircraft. The "L2D4-1" was the cargo transport equivalent. Neither went beyond prototypes. The last in the series, the "L2D5", was basically an L2D4 that was designed to be built with as much non-strategic materials (wood plus steel aircraft alloys) as possible and powered by Kinsei 62 radials, with 1,165 kW (1,560 HP) each, but the prototype was not completed before the end of the Pacific War.

Showa built a total of 416 L2Ds, in addition to the 71 built by Nakajima. The L2D was assigned the reporting name "Tabby" by the Allies. It created a degree of confusion that apparently led to some deadly "friendly fire" incidents. It is unclear if the L2D saw any real use in the postwar period, or if any have survived to this day.

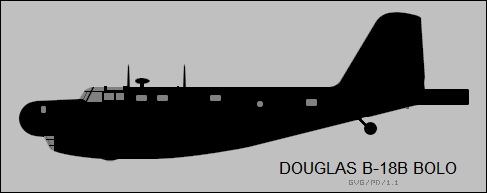

BACK_TO_TOP* The DC-2 not only led to the DC-3 / C-47, it also led to a series of bomber derivatives -- the "B-18 Bolo" and its successor, the "B-23 Dragon".

The Bolo was developed in response to an Air Corps request issued in August 1934 for a new multi-engine bomber to replace the current first-line USAAC bomber, the Martin B-10. The request specified a multi-engined bomber aircraft that could carry a useful bombload at a cruising speed of 354 KPH (220 MPH) at an altitude of 3.05 kilometers (10,000 feet) for ten hours. Top speed was to be 400 KPH (250 MPH). Douglas engineers basically attached the DC-2 wings, tail, and engines to a new bomber fuselage, and entered their candidate, which they designated the "DB-1 (Douglas Bomber 1)", into the competition.

Evaluations of the DB-1 and its competitors, the Boeing "Model 299" and the "Martin 146", were conducted by the USAAC at Wright Field in August 1935. The Model 299 would eventually become the B-17 Flying Fortress, but the Boeing prototype crashed, and was seen as much too expensive anyway. The Martin 146 was an evolved version of the B-10 and basically older technology. The DB-1 was somewhat more state-of-the-art, not to mention cheap, and won the competition.

A batch of 133 was immediately ordered, to include delivery of the DB-1 prototype to the USAAC. The new bomber was given its B-18 designation in January 1936, and the Bolo began operational service with USAAC units in 1937. The B-18 featured Wright R-1820-45 Cyclones with 694 kW (930 HP) each, driving three-bladed variable pitch propellers. While the wing was derived from the DC-2, the wingspan was also shortened by 1.68 meters (5 feet 6 inches). The new fuselage was deeper than the DC-2's, giving the aircraft a whale-like appearance.

The B-18 carried a crew of six and up to 2,040 kilograms (4,500 pounds) of bombs, and was armed with three 7.62-millimeter (0.30-caliber) Browning machine guns, firing from flexible positions in the nose, from the belly, and from a peculiar dorsal turret that looked like a glassed-in hatbox and could be retracted. The B-18 had a range of 1,930 kilometers (1,200 miles) and a top speed of 350 KPH (215 MPH).

The last of the 133 B-18s built was fitted with a power-operated nose turret and given the company designation "DB-2", but the Air Corps wasn't impressed with this feature. Instead, in 1937 they ordered 177 improved "B-18As", followed by another order for 40 in 1938. The B-18A featured uprated Wright R-1820-53 engines with 746 kW (1,000 HP) each, an extended glass nose that gave the aircraft a somewhat more sharklike appearance, and replacement of the odd glass hatbox turret with a dorsal "greenhouse".

The Bolo was the USAAC's firstline bomber in 1940, and indeed 33 were lined up in rows at Hickam Field in Hawaii when the Japanese struck at Pearl Harbor on 7 December 1941, with most of these aircraft destroyed. They were no great loss, since the Bolo's low speed and pathetic defensive armament made combat missions in them over defended territory sheer suicide. The Bolo was quickly replaced in firstline service by better bombers, most ironically the B-17 -- the descendant of the Model 299 that the Bolo had defeated in the USAAC competition in 1935.

___________________________________________________________________

DOUGLAS B-18 BOLO:

___________________________________________________________________

wingspan:

27.28 meters (89 feet 6 inches)

wing area:

89.09 sq_meters (959 sq_feet)

length:

17.27 meters (56 feet 8 inches)

height:

4.62 meters (15 feet 2 inches)

empty weight:

7,144 kilograms (15,750 pounds)

MTO weight:

12,286 kilograms (27,097 pounds)

max speed at altitude:

349 KPH (217 MPH / 189 KT)

cruise speed:

269 KPH (167 MPH / 145 KT)

service ceiling:

7,375 meters (24,000 feet)

range (typical):

1,368 kilometers (850 MI / 739 NMI)

___________________________________________________________________

However, like the DC-3, the Bolo was a reliable, sturdy, and docile aircraft, and 122 were modified by the USAAF for coastal patrol -- a role for which it was perfectly adequate. These aircraft were fitted with a bulbous radome in the nose for Air to Surface Vessel (ASV) radar and a tail "stinger" containing a Mark IV Magnetic Anomaly Detector (MAD) boom. The modified Bolos were apparently designated, when anyone bothered to make the distinction, as "B-18Bs" or, in a few cases, "B-18Cs".

Twenty B-18As were also operated by the Royal Canadian Air Force as "Digby 1s" for coastal patrol until 1943. Some Bolos were converted, in another irony, for use as transports, two of these conversions being given the designation "C-58", and other Bolos were flown as hacks. During the war, 18 B-18As were stripped of most combat gear and used as trainers, being given the new designation "B-18AM", with another batch of 22 B-18As then similarly converted to trainers, to be redesignated "B-18M".

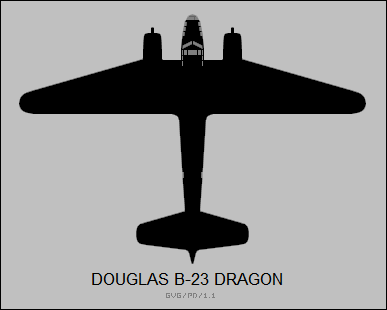

* The Army Air Corps had misgivings about the B-18 early on, as might be expected for an aircraft whose principal virtue was that it was cheap. Although there was thought of fitting the B-18 with uprated Wright R-2600-3 Cyclone 14 radial engines with 1,195 kW (1,600 HP) each, with this improved variant to be given the new designation of "B-22", but it never happened. Instead, in 1938 Douglas came up with a comprehensive redesign of the B-18. The USAAC liked the proposal and ordered 38 of the improved derivatives under the designation "B-23 Dragon". The first B-23 performed its initial flight on 27 July 1939. It was a production-specification machine, a prototype having been judged unnecessary, and the rest of the batch was delivered in 1939.

The B-23 had a general appearance along the lines of the B-18, but it differed greatly in detail, being aerodynamically much cleaner, and was fitted with DC-3 wings, plus a much taller tailfin reminiscent of that of the Boeing B-17. The B-23 was one of the first US bombers with a tail gun position, the tail gunner being armed with a single 12.7-millimeter (0.50-caliber) Browning machine gun on a flexible mount. There were also flexible mounts for a single 7.62-millimeter (0.30-caliber) Browning in the nose, and in a dorsal and a ventral position, for a total defensive armament of four machine guns. Bombload was 2,000 kilograms (4,400 pounds), carried in an internal bomb bay, and the Dragon could also be fitted for photo-reconnaissance.

The B-23 was powered by twin R-2600-3 Cyclone 14s, fitted in lengthened nacelles that featured fully retractable landing gear. In between the cleaner airframe and the more powerful engines, the B-23 was expected to demonstrate substantial performance improvements over the B-18, but evaluations showed that it didn't meet expectations. Furthermore, with a war going on in Europe, by 1940 the B-23 was increasingly seen as inadequate for combat in all respects.

___________________________________________________________________

DOUGLAS B-23 DRAGON:

___________________________________________________________________

wingspan:

28.04 meters (92 feet)

wing area:

92.25 sq_meters (993 sq_feet)

length:

17.8 meters (58 feet 5 inches)

height:

5.63 meters (18 feet 6 inches)

empty weight:

8,659 kilograms (19,089 pounds)

MTO weight:

14,696 kilograms (32,400 pounds)

max speed at altitude:

454 KPH (282 MPH / 245 KT)

cruise speed:

338 KPH (210 MPH / 185 KT)

service ceiling:

9,360 meters (31,600 feet)

range (typical):

2,255 kilometers (1,400 MI / 1,215 NMI)

___________________________________________________________________

The B-23 never saw action. Dragons were used for ocean patrol along the US Pacific coast early in the war, but were then assigned to the training role. In 1942, about 15 were converted to a utility transport configuration and redesignated "UC-67". B-23s were also used as trials and evaluation aircraft.

However useless the B-23 was for combat, it was a solid and airworthy machine, and after the war many B-23s and UC-67s were converted to executive aircraft, mostly by Pan Am, with a crew of two and up to 12 passengers. Some of them survived in civil service into the 1970s. The careers of the Bolo and Dragon were as undistinguished as the C-47's was illustrious. A number of Bolos and Dragons survive today as museum exhibits.

BACK_TO_TOP* Regarding the AC-47s in Vietnam, a crewman named Robert Schlling recalled his adventures in an article from AIR FORCE JOURNAL, Winter 2016:

BEGIN_QUOTE:

Here I was, checked out as an aerial gunner, assigned to a crew and a mission. I stood by the rear door as the cockpit crew started the engines. With a puff of blue smoke, they fired right up. During taxiing to the active runway, we passed many ground troops who never failed to give us "thumbs up" or the "V" for victory. Each time I viewed this gesture, I swelled with pride. AS we turned on to the active runway, we were reminded by the aircraft commander to take our seats and buckle up.

Take-off in the AC-47 was always a little uncomfortable due to the fact that it was a tail dragger, and you had to sit [sideways] at an angle until the rear wheel would lift off the ground. Once we got off the ground and to altitude, we got off our seat and amused ourselves until we got a target. I mainly wrote letters to my family until the silence was broken by the pilot saying: "Crew, we have a target!" Normally, we didn't know where the target was, but upon the pilot's command, everyone in the rear would spring into action.

There were two weapons technicians, or gunners, on each AC-47 gunship. The rest of the crew consisted of a pilot, copilot, loadmaster, and flight engineer. We sometimes carried on board a South Vietnamese Air Force airman to act as our interpreter. ... [The crew] flew many missions together and became very close, like brothers. If necessary, we could each do each others' jobs, to include flying the plane. I remember my first lesson in the right seat. I was taught to keep my eye on the gauges, one hand on the yoke, and the other on the throttles. We all worked together like a Swiss watch, and we knew whatever happened, we had each others' backs.

The loadmaster / flight engineer would attend to the flares, and the gunner would make ready the Miniguns by setting the rounds-per-minute at 4,600, and ensure the gun switch on the control panel was in the OFF position. Upon reaching the target, instructions and coordinates were exchanged between the ground and our pilot and navigator.

Once this occurred and we were cleared to shoot, the pilot would instruct the gunner to arm the guns, saying: "Guns hot!" -- at which time, the gunner would turn the control box switch to HOT. The guns would light up the rear of the aircraft. The gun has an angry, whistling sound. The gun sequence was two guns online, and when they were out of ammo, the number 3 gun was placed on line, and numbers 1 & 2 were reloaded. We were now ready to spoil [the VC's] day.

The flare man would set the flare from zero to 15 seconds, and upon the pilot's command: "Flare away!" -- the flare was tossed out of the plane. After the flare ignited, the pilot would bank left, and when his sight was on the target off his left shoulder, fire the guns. It didn't take too many passes to break off most attacks. Most of the time, we fired from 3,000 to 3,500 feet [about a kilometer]. There were times when it was necessary to fly and shoot lower.

END_QUOTE

* I found some interesting details in the sources that didn't fit conveniently in any of the sections above. One of the details was that apparently some British DC-2s or DC-3s that were pressed into service in Britain were actually fitted with Bristol Pegasus radial engines, though I have no specifics.

Another tale is that of the "DC-2-1/2", which was thrown together on an emergency basis in China, and had one DC-2 wing and one DC-3 wing. A DC-3 operated by China National Aviation Company (CNAC) was forced down by Japanese fighters; the crew and passengers got out, but the Japanese strafed the DC-3 and shot up the right wing. CNAC couldn't find another DC-3 wing, but they did find a spare DC-2 wing; they strapped it to the fuselage of a DC-2 to fly it to the site of the downed DC-3. The wing was fitted and the crew flew the hybrid machine to Hong Kong, reporting no great problems in handling.

* Since this document is part of a series on WINGS OF THE USAAF, I chose to write it about the C-47, not the DC-3, and my apologies to purists who may be annoyed by that decision. The selection of the name "Dakota" is a little more arbitrary, but it does seem like the predominant name for the aircraft in military service, and I like the sound of it anyway.

* Sources include:

I picked up a few details from a Discovery Channel TV show called THE MACHINES THAT WON THE WAR, and I found a surprising number of detailed websites on the Dakota.

* Revision history:

v1.0 / 01 apr 00 v1.1 / 01 jun 00 / Cleanup and tweaks, added B-18 Bolo section. v1.2.0 / 01 feb 03 / Cleanup, added B-23, details on Li-2 & L2D. v1.2.1 / 01 feb 05 / Review & polish. v1.2.2 / 01 feb 07 / Review & polish. v2.0.0 / 01 mar 09 / Went to two chapters, added much more on Li-2. v2.0.1 / 01 feb 11 / Review & polish. v2.0.2 / 01 jan 13 / Review & polish. v2.0.3 / 01 dec 14 / Review & polish. v2.0.4 / 01 nov 16 / Review & polish. v2.0.5 / 01 oct 18 / More on Colombian Turbo Dakotas. v2.0.6 / 01 aug 20 / Review & polish. v2.0.7 / 01 jun 22 / Review & polish. v2.0.8 / 01 may 24 / Review & polish. (+)BACK_TO_TOP