* The Antonov An-24 airliner was introduced into Soviet commercial service in the early 1960s, being widely used and exported. It led to the similarly successful An-26 cargolifter variant.

* In the early 1950s, the primary Soviet civil airliners were the twin-piston Ilyushin Il-12 and its improved successor, the Il-14. The introduction of turboprop propulsion led to work from late 1957 on a successor at the experimental design bureau (OKB in its Russian acronym) run by Oleg K. Antonov. Specifications for the new short-haul airliner included the ability to operate off rough airstrips and in extremes of temperature and environment. Initially, passenger capacity was set at 32 or 40 seats, but during the design phase, the capacity was raised to 44 seats. That change delayed initial flight of the first of two prototypes of the "An-24" to 20 December 1959. Incidentally, first flights of Soviet aircraft had a distinct tendency to take place in late December, it seems in reflection of end-of-year deadlines.

Trials working out well, following the construction of five pre-production machines deliveries of the production "An-24" or "An-24A" to Aeroflot, the Soviet state airline, began in 1962 -- though for various reasons the workup to actual service was delayed somewhat as well, the first scheduled passenger flights beginning in September 1963. The aircraft were built at a state factory in Kyiv. NATO assigned the An-24 the somewhat eccentric reporting name of "Coke".

* The An-24 was comparable to, and definitely reminiscent of, the popular contemporary Dutch Fokker F-27 twin turboliner. Like the F-27, the An-24 was a twin-turboprop short-haul airliner with a high straight wing, tricycle landing gear, and a conventional tail assembly. It was built of aircraft aluminum, using advanced chemical milling techniques that permitted better control over the thickness of skin panels. The aircraft was designed using modular sub-assemblies to ease manufacturing.

The An-24 was powered by twin Ivchenko AI-24 turboprops, driving four-bladed constant-speed reversible props. Early production aircraft had AI-24 Series I engines providing 1,790 kW (2,400 EHP) take-off power each, while later machines went to AI-24 Series II engines with 1,900 kW (2,550 EHP) each. Each engine nacelle included a fire extinguishing system that could be set to an automatic operation mode. A TG-16M auxiliary power unit (APU) turbine was fitted in the left engine nacelle to provide ground power.

The two-spar wing was straight, featuring double slotted flaps inboard of the engines, double slotted flaps outboard of the engines, and ailerons to the wingtips. The wings had a slight anhedral droop outboard of the engines. The tail arrangement was conventional, with the tailplanes featuring a noticeable dihedral. There was a large forward tailfin fillet and a ventral fin, with the ventral fin added after prototype trials revealed yaw instability. Flight surfaces, as well as the engine inlets, used a de-icing system based on hot engine bleed air driven from the engines. In contrast, the windshield and props were electrically deiced.

The landing gear was hydraulically actuated. All three gear assemblies had twin wheels, with the nose gear retracting backward and each main gear assembly retracting forward into an engine nacelle. The nose gear was fully steerable. Tire pressure could be adjusted from the cockpit for different airfield conditions. The An-24A lacked the nose glazing common to Soviet airliners of the period, with the RPSN-2AN Emblema (Emblem) weather radar fitted into the nose instead. The avionics suite also included radios, navaids, an instrument landing system, and an autopilot.

The An-24 had been designed for three crew -- pilot, copilot, and navigator -- but the traditionalism of customers like Aeroflot won out, with a flight engineer and radio operator added. Of course, the An-24 was pressurized and climate-controlled. There was a single door on the left rear with a folding two-section "airstair"; in service, 50 passengers were seated four-across, though lower density configurations were possible. There was also an emergency exit on each side of the fuselage, forward of the wing on the left side of the fuselage and rear of the wing on the right; a baggage compartment fore and aft, with a large cargo door forward on the right that slid in and upward to open, and a smaller service door to the rear on the right; plus toilet, coat closet, and galley in the rear.

VIP versions of the An-24A, designated as "An-24 Salon", were built as well, with luxury interiors for high government and military officials. These machines were operated by the VVS (Voyenno Vozdushniye Sily / Red Air Force) in civil-like color schemes.

BACK_TO_TOP* The An-24 was followed in production by the "An-24B", with the initial prototype -- converted from a production An-24A -- performing its initial flight on 16 November 1965. The An-24B went into production at the Kyiv factory and another state factory at Ulan-Ude in Siberia. The main drive behind development of the An-24B was to alter the design to make it easier to build and to configure as per customer requirement. For example, some customers wanted additional range, so the An-24B could be built with additional fuel tankage in the center wing section.

The only real external recognition feature of the An-24B from the outset was an additional window on each side of the fuselage, though to confuse matters some An-24As would be modified with added windows, too. After early production, An-24Bs were built with single slotted flaps inboard, replacing the original double slotted flaps, which were hard to build. The new single flaps were longer from front to back than the double flaps, in effect increasing the chord of the wings inboard of the engines. In addition, later An-24B production featured twin fixed ventral fins instead of one as a means of improving yaw stability.

While the size of the passenger compartment wasn't changed, accommodations were rearranged to permit a maximum of 52 passengers -- though it made for a cramped and uncomfortable ride, 48 passengers in a single-class configuration being more liveable. A partition could be installed in one of two positions in the passenger compartment for multi-class operation. Some niceties were added as well; believe or not, the original An-24 didn't have overhead baggage racks, and the addition of this feature to the An-24B eliminated the need for passengers to check their small baggage.

All the passenger seats could be removed for cargo operations, with the An-24B able to handle up to 5.4 tonnes (5.95 tons) of cargo. It was also possible to arrange the An-24B for mixed passenger-cargo ("combi") operation, with cargo forward, near the big front loading door, and seats aft. The two sections were separated by the installable partition, giving an option of either 38 or 20 seats. How useful the An-24B was as a cargo hauler is ambiguous: although fairly large items could be loaded using the big forward cargo door, the An-24B didn't have built-in facilities like an overhead winch on a rail for handling cargo. Of course, VIP configurations were flown as well, typically with 20 or 28 seats and multiple compartments, with various luxuries.

* After producing enough An-24s and An-24Bs for domestic use and ensuring the machine was well-validated, in 1962 the Kyiv plant began to produce an export version, the "An-24V". Export machines were not built at the Ulan-Ude plant. There is some confusion between the An-24V and An-24B in Western sources, partly because their designations are very similar in Cyrillic, partly because there wasn't much difference between them. As was typical of Soviet export aircraft, the An-24V was built to two standards: a "standard A" for Warsaw Pact nations that was almost identical to the An-24B, and a "standard B" for everyone else that had less sophisticated avionics. Whatever the standard, the precise avionics fit actually varied according to customer, with some Western avionics provided for locales where it was needed -- for example, aircraft going into airports in the West needed to use Western instrument landing system kit.

BACK_TO_TOP* There had been consideration of a military transport version of the An-24 from early on. Several concepts were drawn up, with one design featuring a tail cargo door and loading ramp, but the decision was made to fly a prototype of a minimum-change military variant of the An-24A, designated the "An-24T". The third An-24 prototype was modified to become the prototype of the An-24T, with flight tests of the militarized machine beginning in September 1961. Trials in 1962 revealed that the VVS actually didn't think a minimum-change derivative of the An-24A was all that useful, with the An-24T prototype seen as lacking range, payload capacity, cargo handling gear, and a ventral hatch for cargo transfer and parachute drops.

The An-24T prototype ended up back in civil service, but the Antonov OKB took the criticisms to heart, and in 1965 converted an An-24A to an "An-24T Mark II" AKA "An-34" configuration. Extra fuel tanks were installed to increase range, while uprated AI-24T engines with 2,100 kW (2,820 EHP) take-off power each provided greater payload capability. A cargo-loading hatch was installed in the belly of the cargo hold, the hatch featuring double doors that opened inward, while cargo-handling gear was fitted.

The belly hatch was hardly an optimum solution for cargo loading issues, since the low belly clearance restricted the height of cargoes that could be loaded through the hatch. However, the VVS found the machine satisfactory and the An-24T -- no "Mark II" in the service designation, since the Mark I had never reached operational service -- went into production at a state factory in Irkutsk, with initial deliveries in 1966 and formal introduction to service in 1967. An "An-24TV" variant was built for the export market, again in two levels of configuration. Very few An-24T/TVs were ever used by civil services.

* The production An-24T clearly differed from the An-24 airliners in that the An-24T only had a few windows on each side, and no doors at the rear of the fuselage. That makes it a bit mysterious as to how the crew got in and out, but it turns out they used the big forward baggage door on the right side of the aircraft; bailing out using that hatch, right into the starboard engine, was problematic to put it mildly, so a hatch was installed behind the nose gear, with the hatch door providing a windbreak for crew escaping the aircraft.

The An-24T also differed from the airliners in that it was fitted with a prominent astrodome for the navigator behind the cockpit, and a spine running from the tailfin fillet up to midwing. Like the An-24B, the An-24T had twin ventral fins. Very early An-24T production had the double slotted inboard flaps, but most were built with the big single-piece flaps.

The belly cargo hatch had a length of about 2.72 meters (8 feet 11 inches) and width varying from 1.25 to 1.4 meters (4 feet 1 inches to 4 feet 7 inches); in production machines, the two doors opened fore and aft. The hatch had been slightly longer and narrower in the prototype, with doors that opened to the sides. There was a powered winch above the hatch -- plus a conveyor system built into the floor, powered by chain drive, for freight handling and parachute dropping. The floor was made of aluminum sheeting backed by plastic foam for light weight. There were 42 tip-up seats along the sides for paratroopers; up to 24 stretchers and a seat for a medical attendant could be fitted for the medical transport mission.

___________________________________________________________________

ANTONOV AN-24T:

___________________________________________________________________

wingspan:

29.2 meters (95 feet 10 inches)

wing area:

72.46 sq_meters (780 sq_feet)

length:

23.53 meters (77 feet 2 inches)

height:

8.32 meters (27 feet 4 inches)

empty weight:

14,970 kilograms (33,000 pounds)

MTO weight:

19,800 kilograms (43,650 pounds)

cruise speed:

450 KPH (280 MPH / 245 KT)

service ceiling:

8,400 meters (18,520 feet)

range (max fuel):

3,000 kilometers (1,865 MI / 1,620 NMI)

range (max payload):

640 kilometers (400 MI / 345 NMI)

___________________________________________________________________

The An-24T was fitted with PSBN-3N Emblema radar, an enhanced version of the PSBN-2N fitted to the An-24A/B that provided improved ground mapping capabilities. Of course other militarized avionics gear was fitted as well. The An-24T actually had a night-capable bombsight system to permit precise airdropping of cargoes. In fact, as per VVS policy at the time, the An-24T could actually be used as a bomber in a pinch, carrying ordnance on two racks that could be installed on each side of the lower fuselage. Somewhat more practically, the external racks could be used to carry paradropped radio beacons and other parachutable packages that didn't "go boom".

* The An-24T proved satisfactory in service, but its take-off performance under "hot & high" (hot weather / high altitude) conditions left something to be desired. In cold weather conditions, the flight surface de-icing system, driving by engine bleed air, drew off too much excess power, with the result that it couldn't be used on take-offs. In addition, the TG-16M APU didn't always provide as much power as needed.

There turned out to be a straightforward solution to the problems. Earlier in the decade, the Tumanskiy engine OKB had developed a compact turbojet, the "RU19-300", for a jet trainer that didn't enter production. Instead of simply discarding the engine, Tumanskiy engineers redesigned it into a combination APU/booster engine, the "RU19A-300", with a thrust of 2.16 kN (220 kgp / 485 lbf). The left engine nacelle of the An-24T was redesigned to accommodate the RU19A-300 instead of the TG-16M, with the resulting new An-24 version designated the "An-24RT" -- where the "R" effectively stood for "reaction", indicating the jet booster.

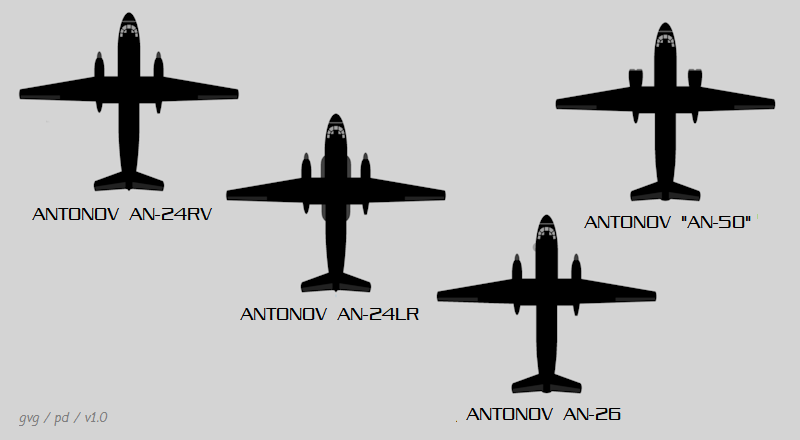

The RU19A-300 fit proved all that was hoped for, providing adequate boost power under difficult take-off conditions, plenty of airflow for the de-icing system, and plenty of power for ground operation. It might seem that asymmetric thrust would have been an issue, but the increment provided by the booster engine was no big problem. In fact, the booster engine was so clearly useful that the decision was made to produce An-24B airliners with the booster engine as well, resulting in the "An-24RV", which gradually replaced the An-24B on the production line. The An-24RV was built in both regular airliner and salon VIP configurations; it was used by Aeroflot and civil air services of Soviet-friendly states.

BACK_TO_TOP* Roughly 1,100 An-24s of all variants were built up to end of production in 1978. The An-24 was a fine "flying truck", able to carry large loads; it was also comfortable and economical to operate, while the RU19A-300 booster engine installed on the An-24RT/RV provided plenty of power for mission equipment. As a result, there were plenty of special-mission variants of the An-24:

Other An-24s were employed in small or single quantities as calibration aircraft for electronic air navigation or landing aid systems; meteorological research; propulsion system testbeds, including one that tested eight-bladed low-noise propellers; and avionics testbeds, including an "An-24T Troyanda" with oversized "cheek" fairings containing experimental antisubmarine warfare (ASW) gear.

* In 1966, the Red Chinese government negotiated the manufacture of the An-24, with the plant in Xian flying the first "Y7", as the type was known in China, in late 1970 -- this machine being effectively an An-24RV. Unfortunately, the upheaval of the Cultural Revolution threw further development of the Y7 off track, with the type only finally entering service in the mid-1980s. Most were delivered to the Chinese military, though some were fitted out as airliners and flown by the Civil Aviation Administration of China (CAAC). China and the USSR were not on good terms during this time, and the Y7s were built outside of license.

In the mid-1980s, a stock Y7 was refitted with winglets, Westernized avionics, and a new interior as the prototype of a "Y7-100", mostly for the export market. A freighter version, the "Y7-100C", was also developed. A version of the Y7-100 with derated engines, intended to improve engine life, was introduced as the "Y7-200", but it was underpowered and was only built in small numbers, if any production machines were built at all.

The Chinese were never all that enthusiastic about the An-24, with only 62 Y7s and about 50 Y7-100s built to the turn of the century. However, Xian continues to improve the Y7 series with help from Russian and Western organizations. Prototypes were flown in the mid-1990s of the improved "Y7-200A" and "Y7-200B" with Pratt & Whitney Canada PW127C turboprops, four-blade Hamilton Standard propellers, a redesigned cabin, and a slight fuselage stretch permitting carriage of up to 60 passengers.

They were followed by the "MA-60", with uprated PW127J turboprops and seating reduced to 56 to improve passenger comfort. Orders have been coming in for the MA-60, with Xian stating that the organization expects to sell hundreds of them. There have also been proposals for a maritime patrol aircraft derivative, the "MA-60MPA", with a search radar in the nose and underwing stores pylons.

BACK_TO_TOP* As noted, early on in the An-24 program there had been talk of developing a cargolifter derivative with a tail loading ramp, but the decision was made to instead produce the somewhat improvised An-24T, with its belly hatch. In the mid-1960s, the Antonov OKB perceived that the Red military seemed more receptive to an optimized cargolifter, and so OKB engineers pulled the old concept plans for an An-24 with a rear loading ramp out of the files, polished up the idea, and pitched it to the authorities.

The key to the offering was a slick new rear loading ramp design that could either be hinged down for "drive-in" loading, or slid under the floor of the cargo hold for loading from a truck tailgate or performing airdrops of cargo. When closed, the ramp formed a tight seal, permitting pressurization of the cargo hold. OKB engineers built a tidy 1/12th scale model to show how the ramp worked. On inspecting the model, the authorities were impressed and promptly gave the go-ahead for development of the "An-26" in March 1968. First flight of the initial An-26 prototype was on 21 May 1969.

Installation of the loading ramp of course meant substantial redesign of the An-24's rear fuselage. The new rear fuselage was 26 centimeters (10.5 inches) longer; the ventral fins of the An-24 had to go away, but they were replaced by strakes flanking the base of the cargo hatch. The strakes not only provided directional stability, but also compensated for turbulence caused by the new rear fuselage scheme that would have otherwise led to increased drag. The tailfin was increased in area, though not in height, while the span of the tailplanes was increased as well.

There was an inclination not to fiddle much with the design of the rest of the An-26 relative to the An-24 to ensure parts commonality, but some changes were made forward, most significantly fit of an observation dome on the left side of the fuselage behind the cockpit, with the optical bombsight fitted there on a swinging mount. The changes to the An-26 resulted in increased weight, so the wings were reinforced and the An-26 was fitted with uprated AI-24VT engines providing 2,100 kW (2,820 EHP), driving improved four-bladed propellers. The RU19A-300 APU/booster was also fitted.

A second An-26 prototype followed later in 1969, with both machines making a visit to the Paris Air Show that year and making a good impression on visitors. NATO assigned the type the reporting name "Curl". The initial production example was rolled out of the Kyiv factory at the end of August, with full series production beginning in 1970. About 1,400 An-26s would be built to end of production in 1986, with about 40% of the total going to the Soviet military, and the rest split evenly between Soviet civil aviation and export users.

* The An-26, as described above, was very much like an An-24 except for the tail section and some changes like the side observation dome. It could easily be confused with an An-24 at first glance, though the strakes on the side of the rear fuselage were an easy giveaway on a second.

The cargo bay had an overhead hoist on a rail for cargo loading. Vehicles could drive up the tail ramp to get on board; if they weren't self-propelled, there was a pulley at the head of the cargo bay to allow them to be pulled on board by an external tractor. Not all An-26s had a floor conveyor system, that being reserved for machines intended for supply paradrops. There were tip-up seats along the walls for troops. While early An-26 production featured the PSBN-3N radar, later production has the more advanced Groza-26 radar. Later production also featured the intake for the RU19A-300 APU/booster moved from the right side of the engine nacelle to the bottom.

* Although the An-26 was meant primarily for military use, a prototype of a civilianized "An-26B" cargolifter was rebuilt from a stock An-26 in 1976. The experiment going well, the An-26B went into service in the early 1980s, with 116 built up to end of production in 1985.

___________________________________________________________________

ANTONOV AN-26B:

___________________________________________________________________

wingspan:

29.2 meters (95 feet 10 inches)

wing area:

74.98 sq_meters (807.1 sq_feet)

length:

23.8 meters (78 feet 1 inch)

height:

8.575 meters (28 feet 2 inches)

empty weight:

15,400 kilograms (33,950 pounds)

MTO weight:

24,400 kilograms (53,790 pounds)

cruise speed:

440 KPH (275 MPH / 235 KT)

service ceiling:

7,500 meters (24,600 feet)

range (max fuel):

2,550 kilometers (1,585 MI / 1,375 NMI)

range (max load):

1,100 kilometers (685 MI / 595 NMI)

___________________________________________________________________

The An-26B differed from the military An-26 by being fitted with civilianized avionics; deleting the side observation bubble, there being no strong need for paradrop capability, to replace it with a fairing; and deleting the tip-up paratrooper seats, with two seats installed for cargo handling crew. The overhead traveling winch was retained, and as with the An-26, some An-26Bs had a rolling conveyor system. These machines were mainly intended for hauling standardized cargo pallets. They had separate climate-control systems for the cockpit and the cargo bay, allowing the cargo bay to be chilled for hauling perishable goods.

There was some investigation from the mid-1960s on a derivative of the An-26 powered by four Ivchenko AI-25 small turbofans, mounted in pairs on a pylon extending under and forward of each wing. This variant was to be designated the "An-50", but the authorities thought the Yakovlev Yak-40 tri-jet, also powered by the AI-25, was a better bet, and the An-50 remained a paper project.

BACK_TO_TOP* As with the An-24, a number of specialized variants of the An-26 were flown:

An-26s were also converted for missions such as weather research, with the type being used for air survey duties and avionics trials as well. Since the fall of the USSR, there has also been a push to refurbish old An-26s to commercial configurations, including at least one modified as a VIP transport and, somewhat more practically, with at least ten converted to the "An-26-100" convertible freight / passenger liner or "combi" configuration. In the mid-1990s, at least one An-26 was converted to the "An-26D" long-range configuration by being fitted with a large conformal external tank on each side of the fuselage.

The Chinese obtained a number of An-26s and reverse-engineered the variant, developing their own copy, the Xian "Y7H". Initial flight of a prototype was in 1988, with the Y7H going into service with the Chinese military in 1992. The Y7H has only been built in small numbers, a few dozen in all, including "Y7H-500" civilianized machines and "Y7H-300" export machines.

BACK_TO_TOP